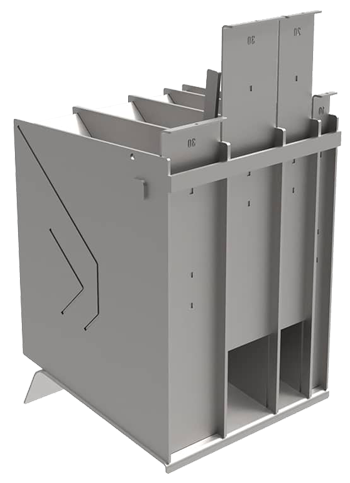

BAFFLE DISTRIBUTORS

Baffle Distributors have reliable static flow rate regulation principal. The flow rate is independant of the downstream water

level. Central locking of all shutters in open or closed position

Field of use:

- These devices are designed for segmenting the initial flow in a group of pre-determined flows with increments of 5, 10, 20, 50, 100, l/ s, according to the type of model required.

- Flow adjustment is achieved by completely opening or closing shutters of different widths. In open position, the equipment maintains the fixed flow, even when the upstream or downstream water level varies appreciably.

- Incoming flow regulation of sewage water in sewage water treatment plants.

Operating principle:

The constant flow is guaranteed by a specially-shaped sill, and one or two deflectors placed at a defined height in order to correct the upstream water level. When the upstream level is low, flow passes freely over the sill. When it increases, the larger jet is trimmed by the deflector. The more the level rises, the more the flow is trimmed, permitting a constant downstream flow. Thus, the most constant flow possible is maintained by entirely static means.

Therefore, the rise follows the nominal flow value: (see HPL 620-5) for a flow rate varying ±5% | for a flow rate varying ±10%.

The addition of a second deflector downstream from the first increases appreciably the value of the rise. The jet, already reduced by the first deflector allows placement even closer to the sill of the second deflector and, thus, forms an orifice of reduced section. Beyond a given upstream level, the first mask is immersed completely and the second mask then activates and again reduces the flow. These deflectors are carefully designed to assure optimal trimming. The admissible rise value for a device with two deflectors increases 190% for a flow rate variation of 5% and reaches 150% in case of a variation of flow of 10%, compared to a model with a single deflector. (See HPL 620-5).

Downstream water level variations have no influence on the flow because of the sill’s slope, calculated to provoke a torrential flow and thus, realize a hydraulic cut at the exit. The formation of a sill allows recovery of energy from the jet and maintenance of slight head loss levels. This head loss varies according to the sill’s level in relation to the deflector.

Conception:

These devices are manufactured in welded steel, to be embedded into the concrete where recesses (losses) have been anticipated. Each baffle distributor is composed of different sized openings in correlation to the required flow.

There are four kind of devices distinguished by their nominal flow rate:

- Type A: 10 l/ s/dm

- Type B: 20 l/ s/dm

- Type C: 50 l/ s/dm

- Type D: 100 l/ s/dm

Each type is given an index of 1 or 2 according to the number of deflectors.

The flow is segmentable:

- Type A: increments are 5 l/s

- Type B: increments are 10 l/ s

- Type C: increments are 50 l/s

- Type D: increments are 100 l/s

For the sake of uniformity, the small shutters are always placed on the left bank. The shutters are opened or closed by a latching system, which is controlled by a single lever. Once the selection of open shutters for achieving the desired flow is determined, the equipment is bolted into position. This system foils tampering with, or modification of the flow by persons unacquainted with the system. Specifically designed to be indifferent to upstream or downstream fluctuations of water level, the equipment provides an efficient means of flow control.

Standard construction:

Baffle Distributors are made of specially-shaped welded steel sheets. The shutters for models A and B are flat and slide in grooves. Models C and D shutters’ are sector-shaped, and rise up and down while rotating around their axis as a result of extra maneuvering efforts caused by increased water height. Tightness is obtained by specially-shaped neoprene joints. Option : manufacturing in stainless steel AISI 304L or 316L.

Coating:

For pieces in A283 Gr D : galvanization (not painted)

For pieces in AISI 304L or 316L : passivation