Get to know what check valves are and their different types. Also, get to know the Duckbill Check Valves, their models and the 10 reasons to include them in your tide back flow project.

WHAT IS A CHECK VALVE?

Check valves in piping systems allow gases and liquids to flow in one direction and prevent fluid reversal. Adequate fluid pressure causes the check valve to open, while opposing fluid causes the check valve to close. Check valves also aid in efficient operation by preventing reverse flows and preventing water hammer. This phenomenon can break valves, pumps or other equipment connected to the pipeline. One of the simplest ways to prevent these episodes is to install check valves where possible.

DIFFERENT TYPES OF CHECK VALVES:

Although there are several types of check valves, each model has its advantages and disadvantages. Among the types most used in sewers are:

Swing or flap check valves:

With a disk usually made of metal, which rotates on a hinge or trunnion in the valve body, thus blocking the flow of fluid. Usually used in large diameter or high flow applications, it has among its disadvantages the possibility of accumulation of debris, which may cause the disc not to close properly and the valve not to seal.

Vibrations or excessive operations can deteriorate the rotating mechanism, stopping correct operation and causing leaks. The presence of upstream flow can impede the correct operation of the valve, causing the obturator to be in an intermediate position.

Ball and spring check valves:

With a metal or coated sphere that seals in the valve body, the seal is proportional to the back pressure of the fluid, a low back pressure upstream could cause a lack of seal. The weight of the valve may limit the use of this type of valve in large dimensions, due to excessive cost or difficulty in installation.

Rubber Duckbill Check Valves:

Inspired by nature, duckbill check valves are simple and efficient. They have a rubber body that remains closed until the correct pressure of gases or liquids causes it to open. Its flexible material and functional design cause the two halves of the opening to form a duckbill-shaped appendage, allowing fluid to move easily towards the outlet.

One of its main attributes is the nonexistence of mechanical elements, which consequently avoids any need for maintenance. It does not need interference to open or close, as the pressure of the fluid divides the two halves, freeing the passage of the liquid. In contrast, fluid pressure in the opposite direction causes the two parts to close. As a result, the fluid does not circulate normally, the greater the counter pressure, the greater the seal.

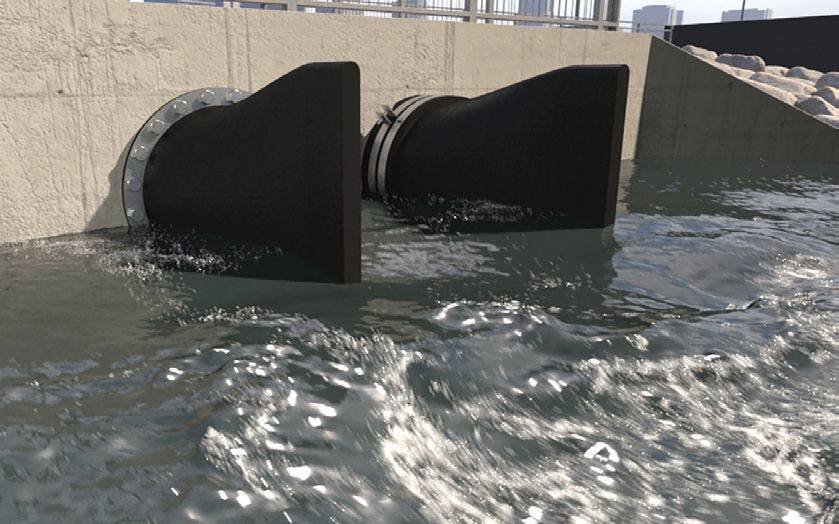

They are especially recommended for the environment sector (clean water or sanitation), the most recurrent uses are in sewage treatment plants, at the end of the outfall lines, and pipes with outlets for lagoons, rivers or the sea.

10 REASONS TO CHOOSE DUCKBILL CHECK VALVES:

- They are extremely effective;

- Non-existent maintenance, with little weight, which makes it an ideal equipment to apply in areas of difficult access or large dimensions;

- Unlike metallic check valves, rubber ones do not suffer mechanical wear, do not rust, jam or seize, providing greater reliability;

- Properly constructed and installed, rubber duckbill valves can remain operational for as long as 30, even 50 years;

- They are completely passive equipment, they do not require any external power source or manual intervention to function;

- Easy installation or replacement;

- They are extremely silent, do not freeze or warp;

- They avoid problems in outfalls to oceanic fronts or lagoons, preventing the invasion of salt water in the collectors, as well as avoiding soil erosion due to high fluid velocities;

- The elastomer composition of duckbill valves has excellent resistance to biological contamination such as barnacles and algae, in addition to good resistance to abrasion;

- Good resistance to corrosion in practically all fluids, in a temperature range from -54ºC to 121ºC.

PROCO PRODUCTS, INC.

Proco Products Inc is an American company, more precisely from the city of Stockton (California), serving the chemical / petrochemical, food, HVAC, industrial, marina, mining, oil, energy, pulp and paper, metal and water segments. With more than 40 years in the market, it is a global leader in the manufacture of expansion joints and check valves. It is with great satisfaction that we announce that KLINGER Portugal is now the exclusive distributor of Proco Products for the national market.

SERIES 700 PROFLEX – RUBBER DUCKBILL CHECK VALVES:

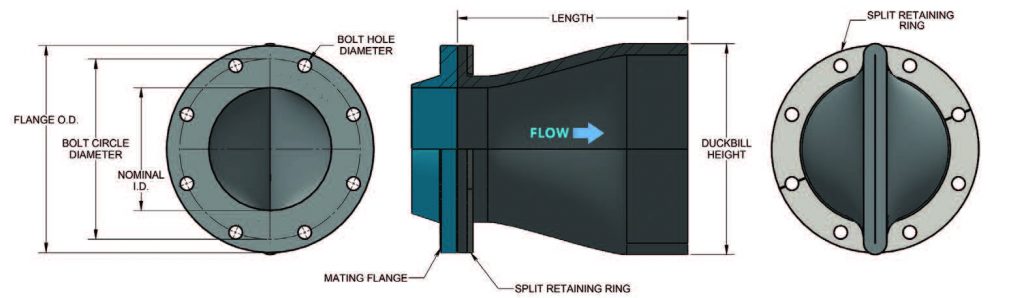

Proco Style 710/711 Pro Flex duckbill check valves:

Flanged check valves. Designed to bolt directly onto existing flanges or new installations. Flanges are drilled to ANSI 125/150#. Other perforation patterns are also available upon request. It can be installed in vertical or horizontal applications. The model 711 is designed for use where the inverted pipe outlet is close to the manhole or outfall floor.

Proco Style 730/731 Pro Flex duckbill check valves:

Sleeve check valves. Designed to easily slide over existing pipe and secured with heavy-duty stainless steel clamps. Can be installed in a vertical or horizontal application. The Model 731 is designed for use where the inverted pipe outlet is close to the manhole or outfall floor.

Proco Style 720 Pro Flex duckbill check valves:

Flanged in line. Designed to fit directly inside a barrel. Flat face flange allowing installation

between existing pipe flanges, eliminating the need for a valve body. Flanges are drilled to ANSI 125/150#. Other perforation patterns are also available upon request.

Proco Style 740 Pro Flex duckbill check valves:

Designed to slide directly into a barrel. Supplied with a stainless steel expandable clamp to secure it in place.