SURFACE AERATORS

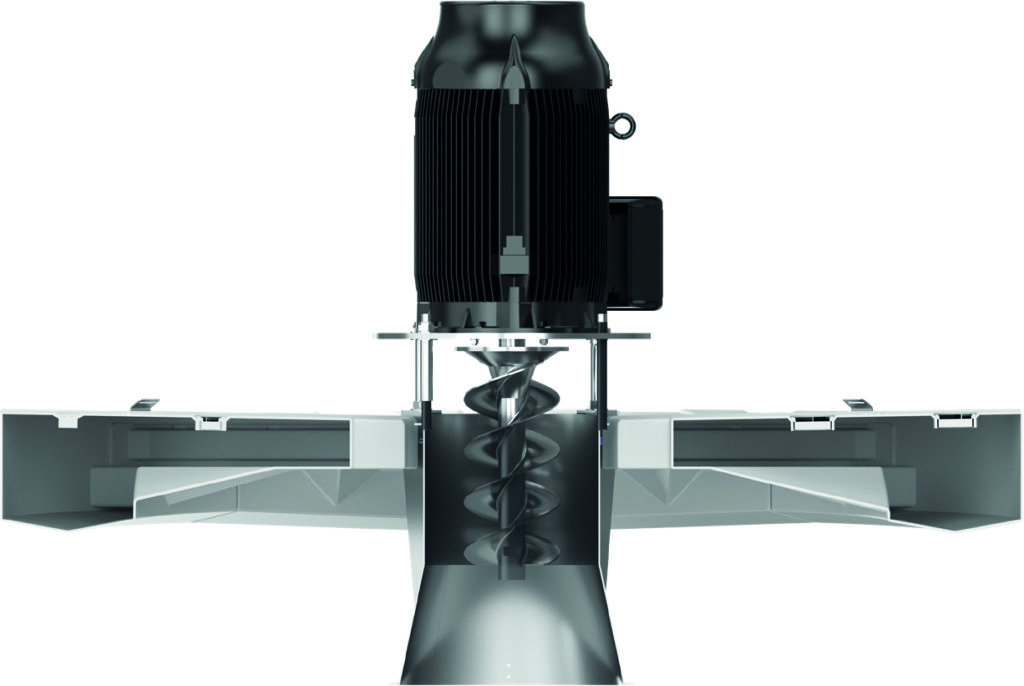

High Speed Surface Aerator

Aeration and mixing of shallow and medium depth tanks, lagoons & ponds

Components:

CORROSION RESISTANT

- The motors are to IE3 standards with enclosures and additional protection plus sealing especially modified to Europelec standards

THE AERATOR UNIT

- Consisting of a propeller

- Stainless steel fins

- Motor support in stainless steel

- Deflector or Spinning device only (depending on the aerator model)

- The float is made up of pre-molded, ultra-resistant, recyclable HDPE construction, mounted on a stainless-steel structure (304L or 316L). The float is highly resistant to shock loading and is mechanical and chemically resistant ensures perfect buoyancy and stability of the aerator.

- Stainless steel draft tubes available

Options

- 304L or 316L

- Side suction for shallow lagoon and extension pipe for deep tanks

- 4 or 6 pole motor (1500 or 1000 rpm)

- Lifting Options: can offer polyester slings which are certified lightweight, easy to handle and offer high chemical resistance

- Mooring rope or guide bar securing system in case of significant liquid level variations

- Lifting Brackets

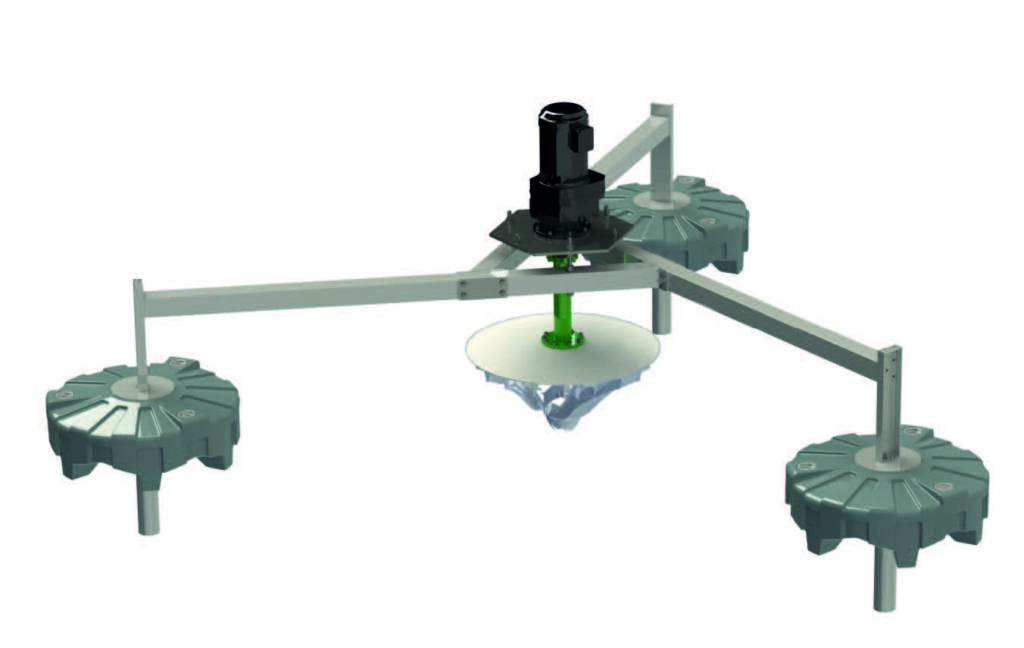

Low Speed Surface Aerator

Fixed or mobile aerator with one of the highest real yields on the market

Main characteristics

- Slow speed aerators used for aeration and mixing of urban and industrial wastewater in various processes

- Provided in either fixed bridge or floating designs

- Provided in either fixed bridge or floating designs

- The TLF Turbine Aerator is one of the most efficient aeration products in the marketplace

- Produces High Mixing and Homogenous Solutions in large lagoons and ASP tanks.

Advantages:

- Significant power range from 1.5kw to 200 kw (higher power on request)

- Maximum oxygenation efficiency and effective mixing

- Various material of construction for all types of applications

- Flexibility and customisation to meet the customer’s requirements

- Reduced noise attenuation to meet local environmental requirments

- Low maintenance floating rotors

- Can be used in deep tanks and large lagoons

- One of the highest real returns in the market

Components:

- IP55 geared motor with IE3 highly efficient rating

- Coupling sleeve and based materials coated with high grade Epoxy paint

- Float can me supplied in various materials including HDPE

- Rotor made of glass fibre reinforced polyester. The GRP has a low

density which allows installation without having to empty the tank and the design also reduces the axial loads on the gearbox.

Options:

- Can also be provided with a cover to avoid aerosols distribution into the atmosphere

- Gear motor and cowling

- Flexible Designs to allow for aerators to be fitted to existing civil structures or steel bridges

- Units can be lifted readily and as one piece allowing simple installation.

- Draft Tubes for deep basins

- Anchoring & Cables for the Floating version

- Possibility of mounting the low-speed aerator on a floating pontoon with or without an access platform