MILTON ROY DOSING PUMPS FOR WATER

LMI PD

Next generation of electromagnetic dosing pumps. Improved drive mechanism. Simplified capacity setting. Advanced electronics. Robust liquid ends.

- 2 models: Manual and Enchanced.

- Maximum flow.: 7,6 l/h.

- Masimum pressure.: 17,3 bar plastic liquid ends and 30,6 bar S.S. liquid ends.

- Ingress protection (NEMA4X; IP65).

- Degassing technology: Stay-Prime.

- Universal voltage 115-230VAC. 1 Phase. 50 and 60Hz.

- Regulated flow accuracy to the oder of ± 3 %.

- Color LCD option, allows easy navigation and configuration with graphical display.

LMI EXCEL AD

Next generation of electromagnetic dosing pumps. LCD user interface with display of the calculated flow rate. M;aximum adaptability -> control can be manual, by pulse, by 4-20 mA signal, sequential via timer, batch injection, pulse division/multiplication, 24 VDC output, remote on/off.

- Maximum flow.: 7,6 l/h.

- Maximum pressure: 17,3 bar.

- Protection IP65.

- Universal power supply: 95 V to 240 V.

- Frequency: 50 Hz to 60.

- Adjusted flow accuracy: to the order of ± 2%.

LMI B

Dry diaphragm or piston electromagnetic pumps. Adapted to most fluids (acids, bases, chlorinated products and others).

- Maximum flow.: 26 l/h.

- Maximum pressure: 10,3 bar.

- Protection IP65.

- Power supply 115 ó 230VAC. 1 Phase. 50 y 60Hz.

- Adjusted flow accuracy: to the order of ± 2%.

LMI C

Dry diaphragm or piston electromagnetic pumps. Adapted to most fluids (acids, bases, chlorinated products and others) .

- Maximum flow.: 30,4 l/h.

- Maximum pressure: 10,3 bar plastic liquid ends and 20,7 bar S.S. liquid ends.

- Protection IP65.

- Power supply 115 ó 230VAC. 1 Phase. 50 y 60Hz.

- Adjusted flow accuracy: del orden de ± 2 %.

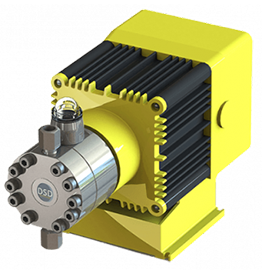

LMI C TECNOLOGIA DSD

Electromagnetic dosing pump. Unbreakable rigid diaphragm liquid end. 6 mWC suction head. Environmental protection (REACH).

- Reduced operating and maintenance costs.

- Flow rate: From 0,009 ml/h to 2,14l/h.

- Maximum pressure: 25 bar plastic liquid ends and 50 bar S.S. liquid ends.

- Matériaux proposés: PVC, Inox (Design pour produits visqueux).

- Protection IP65.

- Power supply 115 ó 230VAC.1 Phase. 50 y 60Hz.

- Accuracy: ± 2 % over a range of 10 to 100% of the nominal flow rate.

PROTEUS B

Dosing pumps engineered to meet today’s most demanding standards for accuracy, reliability, and process control flexibility.

- With LCD screen for display of the flow rate. Maximum adaptability -> Manual Control. By pulses. By 4-20mA signal (Modbus). Timed By batches. Start-up / Remote stop. Level Detection.

- Maximum flow: 68,1l/h..

- Maximum pressure: 12 bar.

- +/- 1% steady state accuracy over 1000:1 turndown ratio.

- Power supply 100 ó 240VAC. 1 Phase. 50 y 60Hz.

- Upgraded NEMA 4X/IP 65 housing and protective cover for the harshest environments.

PROTEUS C

Dosing pumps engineered to meet today’s most demanding standards for accuracy, reliability, and process control flexibility.

- With LCD screen for display of the flow rate. Maximum adaptability -> Manual Control. By pulses. By 4-20mA signal (Modbus). Timed By batches. Start-up / Remote stop. Level Detection.

- Maximum flow: 200,6l/h..

- Maximum pressure: 12 bar.

- +/- 1% steady state accuracy over 1000:1 turndown ratio.

- Power supply 100 ó 240VAC. 1 Phase. 50 y 60Hz.

- Upgraded NEMA 4X/IP 65 housing and protective cover for the harshest environments.

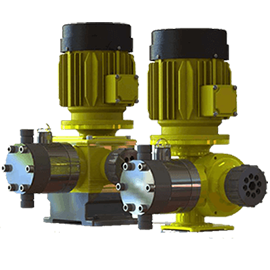

G SERIES (GA-GM-GB)

Dosing pumps with mechanically-actuated diaphragms for water plants. The most reliable mechanically and hydraulically on the market. three models of compact and lightweight dosing pumps.

- Maximum flow: 1.200 l/h.

- Maximum pressure: 12 bar.

- Maximum suction height: 4 m – water.

- Output regulation accuracy: ± 2%.

- ATEX.

G SERIES (GA-GM-DSD)

Series “G” series electromechanical rigid membrane metering pumps. With the benefits of a piston and the tightness of a membrane. It has a robust and compact design with high suction capacity (6 mca). Especially indicated for chemical dosing. In accordance with REACH regulations.

- Flow rate: from 0.1 l/h to 11.95 l/h.

- Pressure: 35 bar Plastic liquid end, and 70 bar for Metal liquid end.

- Stainless steel liquid end, special for viscous products <650cps.

- Accuracy: ± 2% in a range of 10% to 100% of the nominal flow.

- ATEX.