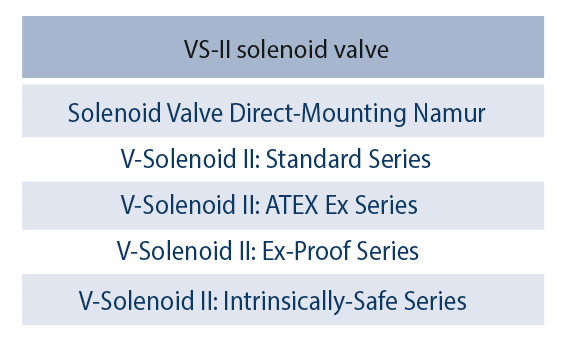

SOLENOID VALVE

A solenoid valve is an electrically controlled valve.

The valve features a solenoid, which is an electric coil with a movable ferromagnetic core (plunger) in its center.

When electrically energized or de-energized, they either shut off or allow fluid flow.

Solenoid valves are used wherever fluid flow has to be controlled automatically.

FEATURES

- Multi-million cycle life reliability. The innovative design and all composite construction means the V-Solenoid II™ is not affected by wear or corrosion

- Set 5/2 or 3/2 function simply by turning the rotary sealing plate 180°, dramatically reducing parts inventory

- High airflow: Cv > 1.1 (1100 L/min) (I-Safe Cv=0.8)

- Manual override built in – no extra parts required

- Operating temperature range: -4°F to +140°F (-20°C to +60°C)

- For extreme environmental corrosion protection, all port threaded inserts and armature components can be supplied in stainless steel

- Direct mounting conforms to Namur VDI/VDE 3845 standard

- Exhaust feedback – provides spring chamber with instrument air preventing corrosion

- Very competitively priced with a wide variety of available options

PATENTED POPPET VALVE DESIGN

- Unique patented poppet valve technology provides high flow, fast response, high temperature range and multi-million cycle life reliability

- Patented poppet valve design minimizes friction by utilizing dual static rolling diaphragmpoppet seals

- Advantage of this design is its suitability for cryogenic environments. Wide operating temperature range -4°F to +140°F (-20°C to +60°C)

PATENTED ROTARY SEALING PLATE

- By turning the patented rotary sealing plate 180° the operating mode can be easily changed from 5/2 to 3/2 function

- The V-Solenoid II can to be used on both double acting and single acting actuators

- Many competitors’ solenoid valves either work 5/2 or 3/2 function requiring stocking for both solenoid valves