DUAL PLATE WAFER CHECK VALVE

The dual plate wafer check valve is one of the most compact check valves.

This valve design is the result of attempts to provide an alternative solution to the problems associated with swing check valves.

Compared to a conventional swing check valve, it is much stronger, lighter and smaller in size.

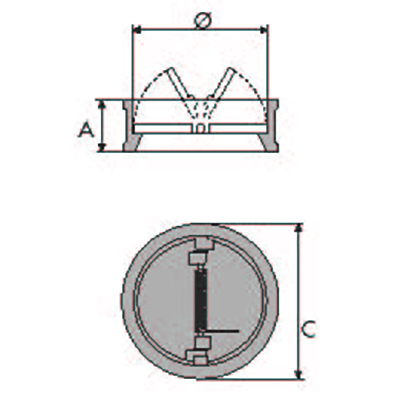

The two plates of the dual plate check valve are hinged vertically in the center, eliminating the effect of gravity in horizontal installations.

When fluid enters the valve, pressure opens the flaps, stretching the spring.

When the valve closes, the flow cushions the plates and seat, so the risk of slamming is negligible.

Dual Plate Wafer Check Valve KRD-DPC

Features

- Cast steel body construction providing liberal strength to meet most conditions

- A choice of metal-to-metal or soft sealing

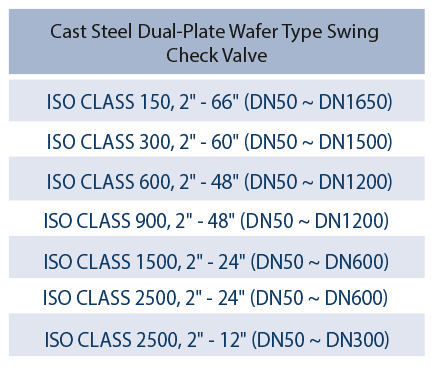

- Full range of pressure class and sizes

- Variety of body and disc materials

- Savings in price and installation cost compared to coventional check valves

Temperature

- Metal seat: -29°C to 450°C

Standards

- Basic design to API 594

- Face-to-Face acc. to API 594

- Flange Dimensions acc. to ASME B16.5

- Inspection & test according to API 598

DUAL PLATE WAFER CHECK VALVE KRD-DPC DATA SHEET (EN)

Dual Plate Wafer Check Valve IDP

Flange connection PN 10/16

Features

- Application: liquids and gases

- Compact

- Easy installation

- Horizontal – or vertical mounting

- Material: Cast iron GG25

- Pressure class: PN 16

- Disc: Stainless steel AISI 304

- Spring: Stainless steel

- O-rings: EPDM

- Options: House and disc in other materials; Dimensions up to DN600; Other connections and pressure stages

Temperature

- -10ºC to 100ºC