TIDE BACKFLOW PREVENTION

Tide Backflow Prevention: circular, square and rectangular gate and duckbill check valves. Sewage treatment, outfalls, and tidal operations.

ROUND OR RECTANGULAR PENSTOCK

Round or rectangular penstock to be wall-mounted or flanged, intended to prevent backflow and commonly installed at the end of a line, as a check valve. Flap gate.

Carbon or stainless steel fabricated construction, with tight sealing by means of an elastomer seal.

Available in a wide range of dimensions and for many different pressure heads.

May include a counterweight for adjustment and control of the opening.

ROUND FLAP GATE DATASHEET (EN)

SQUARE FLAP GATE DATASHEET (EN)

DUCKBILL CHECK VALVES

The Rubber Duckbill Check Valves are a cost effective way to control back pressures from sewage treatment plants, outfalls and tidal operations. They are a fully passive flow device requiring neither maintenance nor any outside sources of power or manual assistance to operate.

Offered as direct replacements for ineffective and maintenance ridden flap type check valves,

commonly known to seize, rust and bind in unwanted positions. Unlike flap type valves, the rubber duckbill check valves will handle large obstructions without jamming or having swing gates binding open.

Our valves provide backflow protection from:

» Sewage slurries

» Outfalls to ocean fronts from heavy rainfall activity

» Prevention from land erosion due to back flow conditions

» Protection from saltwater to fresh water ponds and catch basins and numerous other water based applications

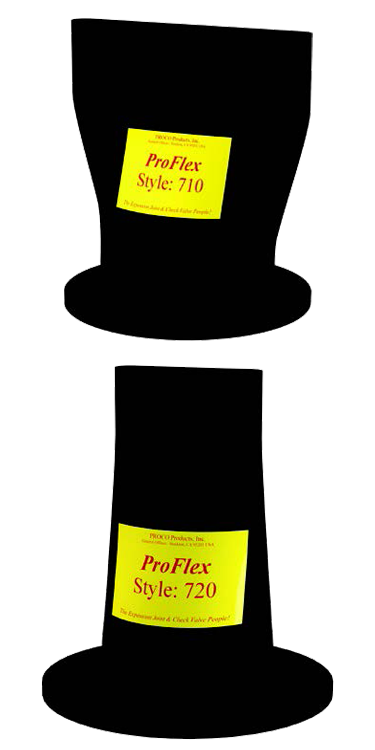

Style 710: Flanged

Designed to bolt directly to existing flanges or new installations, flanges are drilled to ANSI 125/150# standard. Other drilling standards are also available upon request. The style 710 can be installed in either vertical or horizontal applications.

Style 711/731 Flanged/Slip-on Slope Bottom Check Valves:

Designed for installation on pre-existing or new pipe lines such as manholes, outfalls, vaults, where the outfall invert of the pipe is close to the floor of the manhole or outfall. Can be engineered into the pipe layout with little concern for outfall clearance due to its “low slope” design.

Style 720: Flanged In-line:

Designed to fit directly inside of an existing pipe. Supplied with a flat face rubber flange which allows installation between existing pipe flanges eliminating the requirement for a valve body. Flanges are drilled to ANSI 125/150# standard. Other drilling standards are

also available upon request.

Style 730: Sleeve Type:

Designed to easily slip over an existing pipe, and is affixed with heavy-duty stainless steel clamps. Can be installed in either a vertical or horizontal application.

Style 740: Slip In-Inline:

Designed to slip directly inside of an existing

pipe. Supplied with a stainless steel expandable clamp to secure it in place.