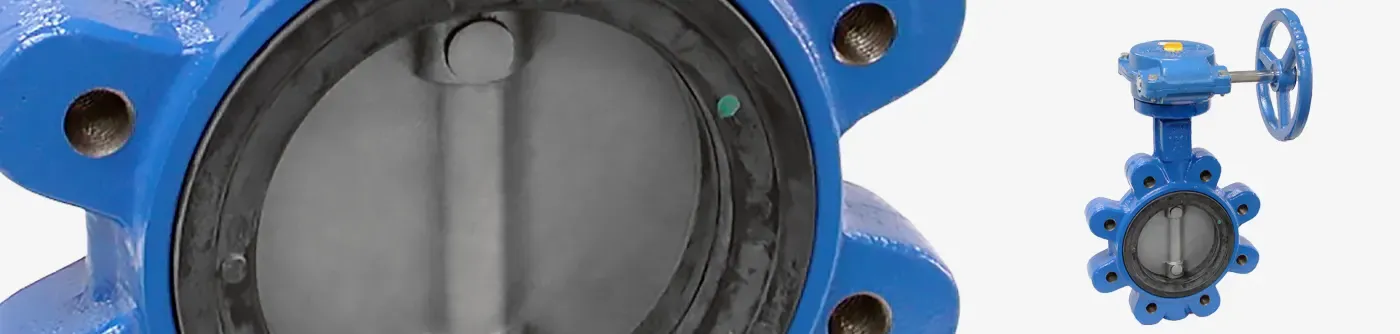

CONCENTRIC BUTTERFLY VALVE

Concentric Butterfly Valve: designed for general industrial applications, with different types of configuration and construction, according to the application needs. Wafer type construction for mounting between flanges, LUG type and flanged in accordance with the different types of existing flange standards (DIN, ANSI, BS, JIS).

Features

- Suitable for use in HVAC, irrigation, industrial applications where positive shutoff is required

- Single through-put shaft provides most economical pricing

- 10 position lever or gear operation

- Alloy material available on request

Standards

- End dimensions acc. to DIN2633

- Inspection test acc. to EN12266

Limitation

- Do not use EPDM when hydrocarbons are present.

- Kindly anticipate increased torque for PTFE coated disc + PTFE seat option; gear operation recommended for sizes 4”.

- End-of-line service at half rating

Options

- Double “half pin” style available for increased performance and lifecycle

- Coated disc available in: rubber, PTFE, nylon