MILTON ROY DOSING PUMPS

LMI PD

Next generation of electromagnetic dosing pumps. Improved drive mechanism. Simplified capacity setting. Advanced electronics. Robust liquid ends.

- 2 models: Manual and Enchanced.

- Maximum flow.: 7,6 l/h.

- Masimum pressure.: 17,3 bar plastic liquid ends and 30,6 bar S.S. liquid ends.

- Ingress protection (NEMA4X; IP65).

- Degassing technology: Stay-Prime.

- Universal voltage 115-230VAC. 1 Phase. 50 and 60Hz.

- Regulated flow accuracy to the oder of ± 3 %.

- Color LCD option, allows easy navigation and configuration with graphical display.

LMI EXCEL AD

Next generation of electromagnetic dosing pumps. LCD user interface with display of the calculated flow rate. M;aximum adaptability -> control can be manual, by pulse, by 4-20 mA signal, sequential via timer, batch injection, pulse division/multiplication, 24 VDC output, remote on/off.

- Maximum flow.: 7,6 l/h.

- Maximum pressure: 17,3 bar.

- Protection IP65.

- Universal power supply: 95 V to 240 V.

- Frequency: 50 Hz to 60.

- Adjusted flow accuracy: to the order of ± 2%.

LMI B

Dry diaphragm or piston electromagnetic pumps. Adapted to most fluids (acids, bases, chlorinated products and others).

- Maximum flow.: 26 l/h.

- Maximum pressure: 10,3 bar.

- Protection IP65.

- Power supply 115 ó 230VAC. 1 Phase. 50 y 60Hz.

- Adjusted flow accuracy: to the order of ± 2%.

LMI C

Dry diaphragm or piston electromagnetic pumps. Adapted to most fluids (acids, bases, chlorinated products and others) .

- Maximum flow.: 30,4 l/h.

- Maximum pressure: 10,3 bar plastic liquid ends and 20,7 bar S.S. liquid ends.

- Protection IP65.

- Power supply 115 ó 230VAC. 1 Phase. 50 y 60Hz.

- Adjusted flow accuracy: del orden de ± 2 %.

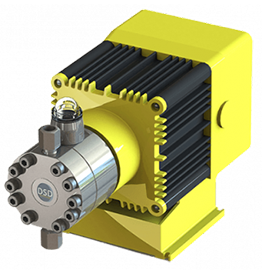

LMI C TECNOLOGIA DSD

Electromagnetic dosing pump. Unbreakable rigid diaphragm liquid end. 6 mWC suction head. Environmental protection (REACH).

- Reduced operating and maintenance costs.

- Flow rate: From 0,009 ml/h to 2,14l/h.

- Maximum pressure: 25 bar plastic liquid ends and 50 bar S.S. liquid ends.

- Matériaux proposés: PVC, Inox (Design pour produits visqueux).

- Protection IP65.

- Power supply 115 ó 230VAC.1 Phase. 50 y 60Hz.

- Accuracy: ± 2 % over a range of 10 to 100% of the nominal flow rate.

PROTEUS B

Dosing pumps engineered to meet today’s most demanding standards for accuracy, reliability, and process control flexibility.

- With LCD screen for display of the flow rate. Maximum adaptability -> Manual Control. By pulses. By 4-20mA signal (Modbus). Timed By batches. Start-up / Remote stop. Level Detection.

- Maximum flow: 68,1l/h..

- Maximum pressure: 12 bar.

- +/- 1% steady state accuracy over 1000:1 turndown ratio.

- Power supply 100 ó 240VAC. 1 Phase. 50 y 60Hz.

- Upgraded NEMA 4X/IP 65 housing and protective cover for the harshest environments.

PROTEUS C

Dosing pumps engineered to meet today’s most demanding standards for accuracy, reliability, and process control flexibility.

- With LCD screen for display of the flow rate. Maximum adaptability -> Manual Control. By pulses. By 4-20mA signal (Modbus). Timed By batches. Start-up / Remote stop. Level Detection.

- Maximum flow: 200,6l/h..

- Maximum pressure: 12 bar.

- +/- 1% steady state accuracy over 1000:1 turndown ratio.

- Power supply 100 ó 240VAC. 1 Phase. 50 y 60Hz.

- Upgraded NEMA 4X/IP 65 housing and protective cover for the harshest environments.

G SERIES (GA-GM-GB)

Dosing pumps with mechanically-actuated diaphragms for water plants. The most reliable mechanically and hydraulically on the market. three models of compact and lightweight dosing pumps.

- Maximum flow: 1.200 l/h.

- Maximum pressure: 12 bar.

- Maximum suction height: 4 m – water.

- Output regulation accuracy: ± 2%.

- ATEX.

G SERIES (GA-GM-DSD)

Series “G” series electromechanical rigid membrane metering pumps. With the benefits of a piston and the tightness of a membrane. It has a robust and compact design with high suction capacity (6 mca). Especially indicated for chemical dosing. In accordance with REACH regulations.

- Flow rate: from 0.1 l/h to 11.95 l/h.

- Pressure: 35 bar Plastic liquid end, and 70 bar for Metal liquid end.

- Stainless steel liquid end, special for viscous products <650cps.

- Accuracy: ± 2% in a range of 10% to 100% of the nominal flow.

- ATEX.

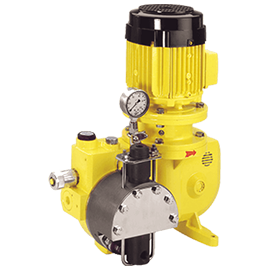

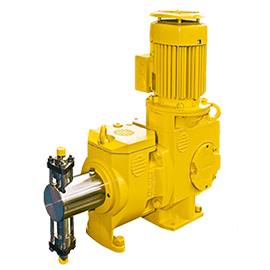

MROY XA E XB

Hydraulic diaphragm metering pump. With more than 50 years in the market dosing chemicals. It is the most installed Pump Model in the world of Industry and Water Treatment (Services of cooling towers and boilers).

- Maximum flow: 310 l/h.

- Maximum pressure: 123 bar.

- Maximum temperature of pumped fluids:

- +90° for metallic liquid end.

- +50° for plastic liquid end.

- Regulated flow accuracy: ± 1% within the regulation field of 10 to 100%.

- Possibility of supply with double liquid end (duplex).

- Can be compatible with API standard 675.

- ATEX.

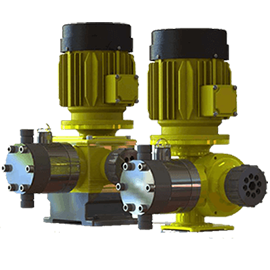

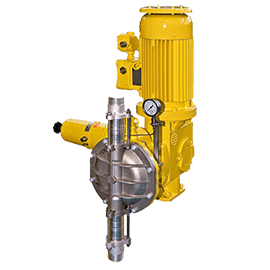

MROY A, B, D

Dosing pump with hydraulically actuated diaphragm. It is the most robust and reliable Pump Model installed in the world of Industry and Water Treatment.

- Maximum flow: 1110 l/h.

- Maximum pressure: 28 bar.

- Maximum temperature of fluid to pump:

- +90° for metallic liquid end.

- +50° for plastic liquid end.

- Regulated flow accuracy: ± 1% within the regulation field of 10 to 100%.

- Possibility of supply with double or triple liquid end (duplex / triplex)

- Can be compatible with API standard 675.

- ATEX.

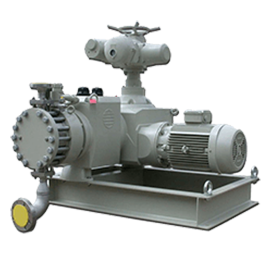

MILROYAL D

High-end industrial metering pump, with plunger or hydraulic membrane for low flow rates and high pressures. Suitable for reagents of high value and critical in the process.

- Flow: from 0,1 l/h to 347 l/h

- Maximum pressure: 500 bar.

- Precision: ±1%.

- Special single and double metal membrane liquid ends.

- Process fluid temperature: from -5°C to +70°C (max. +50° in plastic version).

- Possibility of supply with double or triple liquid end (duplex / triplex).

- Can be compatible with API standard 675.

- ATEX.

MILROYAL TECNOLOGIA DSD

High-end industrial dosing pump, for micro flow rates and high pressures. Virtually indestructible rigid membrane. With the benefits of a plunger and the tightness of a membrane. Robust and compact design with high suction capacity (6 mca). Special for chemical dosing. In accordance with REACH regulations.

- Flow: from 0,01 l/h to 10,08 l/h.

- Pressure: 35 bar for plastic liquid ends and 98 bar for metal liquid ends.

- Precision: ±1%.

- Special metalic liquid ends for high viscosity >7,000cps.

- Process fluid temperature: +50ºC.

- Possibility of supply with double liquid end (duplex).

- Can be compatible with API standard 675.

- ATEX.

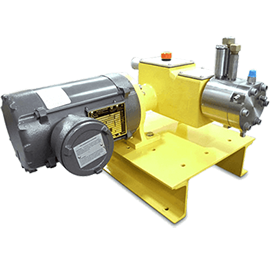

PRIMEROYAL K (PK)

High-end industrial metering pump, with plunger or hydraulic membrane for low and medium flow / low and high pressures.

- Flow: from 0,4 l/h to 2.062 l/h.

- Maximum pressure: 930 bar.

- Precision: ±1%.

- Process fluid temperature: -10ºC/+95ºC for -10ºC / +150ºC for hydraulic membrane, and +10ºC/+50°C for plastic liquid end.

- Possibility of supply with double or triple liquid end (duplex/ triplex).

- Can be compatible with API standard 675.

- ATEX.

PRIMEROYAL K (PKG)

High-end industrial dosing pump, with GSD hydraulic membrane, for medium / low flow rates and medium pressures.

- Flow: from 10 l/h to 2.500 l/h.

- Maximum pressure: 37 bar.

- Precision: ±1%.

- Process fluid temperature: 10ºC/+75ºC for Metal liquid ends, and +10ºC/+50°C for plastic liquid ends.

- Possibility of supply with double or triple liquid end (duplex / triplex).

- Can be compatible with API standard 675.

- ATEX.

PRIMEROYAL L (PL)

High-end industrial metering pump, piston or hydraulic membrane for low flow rates / high pressures and high flow rates / low pressures.

- Flow: from 0,82 l/h to 4.410 l/h.

- Maximum pressure: 1.000 bar.

- Precision: ±1%.

- Process fluid temperature: -10ºC / +95ºC with plunger. -40ºC / + 150ºC with hydraulic membrane. +10ºC / +50°C in Plastic version.

- Possibility of supply with double or triple liquid end (duplex/ triplex).

- Can be compatible with API standard 675.

- ATEX.

PRIMEROYAL L (PLG)

High-end industrial dosing pump, with GSD hydraulic membrane, for medium / low flow rates and medium pressures.

- Flow: from 20 l/h to 3.300 l/h.

- Maximum pressure: 45 bar.

- Precision: ±1%.

- Process fluid temperature: 10ºC / + 75ºC for Metal liquid ends, and +10ºC / +50°C for plastic liquid ends.

- Possibility of supply with double or triple liquid end (duplex / triplex).

- Can be compatible with API standard 675.

- ATEX.

PRIMEROYAL N (PN)

High-end industrial metering pump, with plunger or hydraulic membrane for low flow rates / high pressures and high flow rates / low pressures.

- Flow: from 4,4 l/h to 9.863 l/h.

- Maximum pressure: 1.000 bar.

- Precision: ±1%.

- Process fluid temperature: -10ºC / + 95ºC with plunger, -40ºC / +150ºC with hydraulic membrane, and +10ºC / +50°C in Plastic version.

- Possibility of supply with double or triple liquid end (duplex / triplex).

- Can be compatible with API standard 675.

- ATEX.

PRIMEROYAL P (PP)

High-end all-metal industrial metering pump, with plunger or hydraulic membrane for high flow rates / low-medium pressures.

- Flow: from 166 l/h to 15.665 l/h.

- Maximum pressure: 310 bar.

- Precision: ±1%.

- Process fluid temperature: -10ºC / +95ºC with plunger. -40ºC / +150ºC with hydraulic membrane.

- Possibility of supply with double or triple liquid end (duplex/ triplex).

- Can be compatible with API standard 675.

- ATEX.

PRIMEROYAL R (PR)

High-end all-metal industrial metering pump, with plunger or hydraulic membrane for high flow rates / low-medium-high pressures.

- Flow: from 95 l/h to 15.615 l/h.

- Maximum pressure: 1.000 bar.

- Precision: ±1%.

- Process fluid temperature: -10ºC / +95ºC with plunger, and -40ºC / +150ºC with hydraulic membrane.

- Possibility of supply with double or triple liquid end (duplex / triplex).

- Can be compatible with API standard 675.

- ATEX.

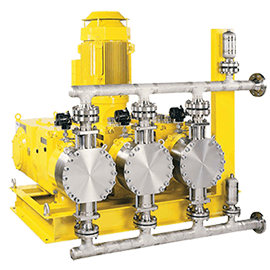

SÉRIE MEGAROYAL

MEGAROYAL pumps provide accurate injection of high flow polymer solutions into an extruder to produce raw plastic pellets which are used in the global plastic market.

The polymer manufacturing process requires performant and flexible pumps that can adapt to a variety of production demands.

The MEGAROYAL triplex monobloc pumps are equipped with a VFD motor that adjusts to changes in production flow rates as needed.

- Deliver constant flow rates 7,000 LPH max (1,850 GPH max) at 70 bar / 1,015 psi discharge pressure.

- Heating jackets maintain the right temperature (+90°C / +194°F) of the polymer solution in order to maintain the required viscosity.

- Special check valves designed to handle viscous polymer solutions (10,000 cps).

- Capable of supporting the continuous operation of feeding the extruder.

- The accuracy of the MEGAROYAL dosing pump allows the synchronization with the extruder rotation speed to produce a constant quality of the plastic pellet.

- High level of accuracy, linearity and repeatability adapts to the production flow as needed.