Get to know the the SEALING ON A ROLL KLINGER SEALEX, versatile and safe solution for every eventuality.

With SEALING ON A ROLL KLINGER SEALEX you are always prepared! No matter what the unexpected, the result will always be a reliable and easy to use sealing. Specially processed, 100% pure PTFE on a roll, SEALEX has excellent chemical resistance properties and can be used pratically anywhere. Available in a wide range of thicknesses and lengths, its versatility also reduces maintenance and storage costs.

What is so unique about KLINGER SEALEX?

» Excellent resistance properties to chemical attack

» Wide temperature range

» Available in roll form which helps reduce storage space

» Longer life and trouble-free sealing

» Easy to install

KLINGER SEALEX MATERIALS

Made from 100% pure PTFE from a unique, physically networked fibrillated material. Composed of specially prepared fluorocarbons with excellent resistance to aggressive chemicals as well as offering secure sealing under high pressures.

It does not allow bacterial growth or cause product contamination and it is FDA compliant. It has virtually no shelf-life concerns since PTFE is unaffected by normal environmental conditions.

Important approval certifications and tests KLINGER SEALEX:

» DVGW: Registration nº DG-5127BR0551

» BAM/oxygen: tested for oxygen at 60 bar and 60ºC (not for liquid oxygen)

» TA-Luft: Tested at 150ºC

» FDA conform, including adhesives

» Certified according to DIN EN ISO 9001:2008

TEMPERATURE AND PRESSURE CONDITIONS

KLINGER SEALEX resists chemical attack with excellence, withstands temperatures up to 500ºF (260ºC) and a maximum pressure of 2000PSI (138bar). Suitable for cryogenic use -321ºF (-196ºC) and allows use in applications up to 150 bar internal pressure.

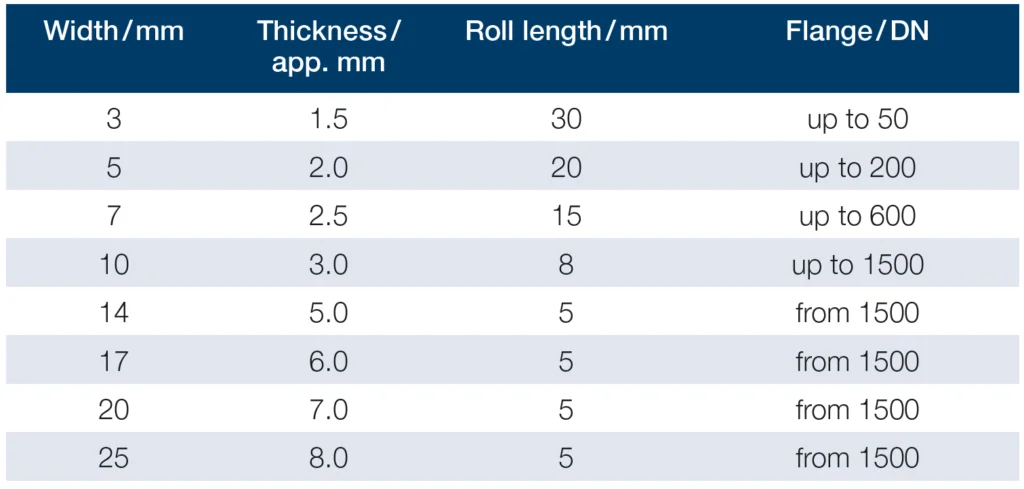

Avaliable 8 different width / thickness ratios:

SEALING

Due to its characteristics, with the KLINGER SEALEX, sealing problems are non-existent. Its soft, highly compressible seal effectively fill flange imperfections for a tight, leak-free seal. Good creep resistance to bolt torque retention properties.

MAIN APPLICATIONS

Suitable when the sealing surface or the flange stability prevents the successful use of a conventional seal. KLINGER SEALEX is also recommended when the flange sealing geometry requires an intricate gasket form, which is both difficult to assemble and uneconomical to manufacture. Furthermore this product is recommended when the flange material allows only low bolt loads to be used to seat the gasket but the media in the system and the internal pressure require high sealing.

SOLUTIONS

» Fume ducts

» Concrete lids

» Heat exchangers

» Fiberglass reinforced plastic vessels

» Pump or compressor housing flanges

» Steam vessel flanges

» Glass joints

» Ceramic joints

» Water systems

INSTRUCTIONS – KLINGER SEALEX

Use a size with nominal width of between 1/3 and 1/2 of the effective flange sealing width.

- Make sure that the sealing flanges are clean.

- Cut off a length of Sealex® just a little longer than the actual circumference of the perimeter of the seal.

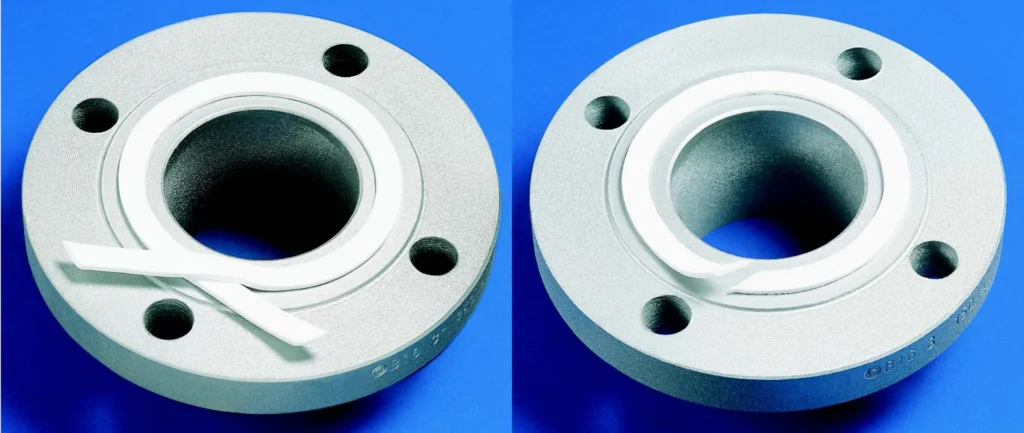

- Peel off the adhesive protection strip, and press the Sealex® into position. Cross the free ends of the Sealex® adjacent to the bolt hole.

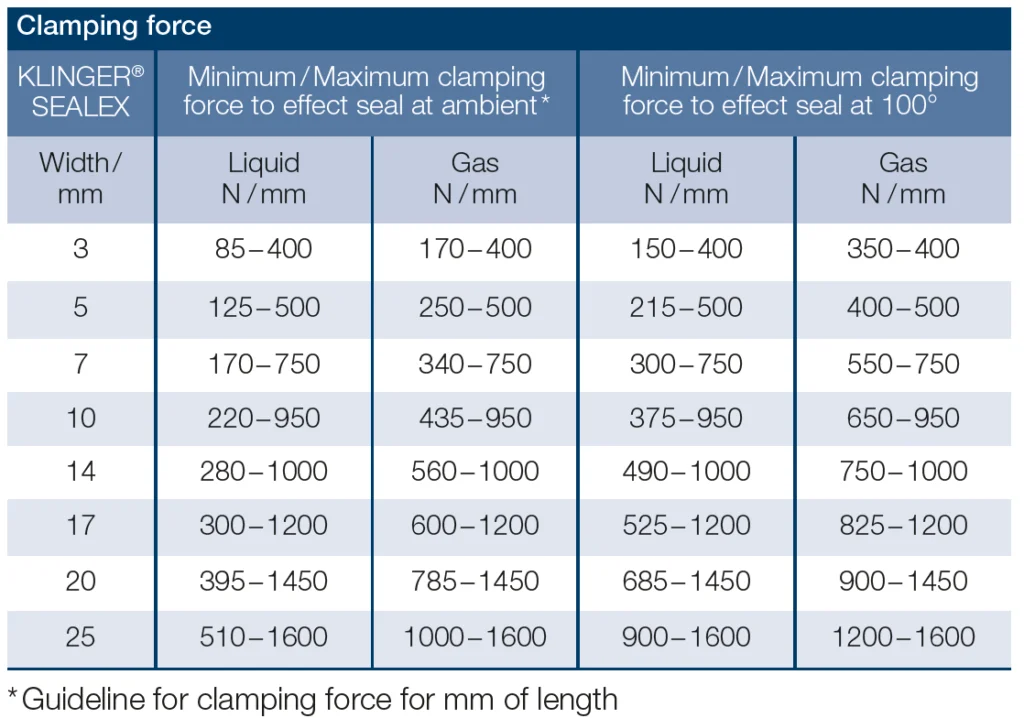

- Bolt up the mating surfaces using the recommended clamping force and bolt tightening patterns.

Contact our Industry Sales Director Hélder Almeida:

???? h.almeida@klinger.pt

???? +351 229 470 915