ELECTRIC ACTUATORS

Electric actuators are often used to control the opening and closing of valves in industrial systems. They serve to automate valve operation, allowing more precise and efficient control of the flow of liquids, gases or vapors in a system.

Electric actuators can be used in a wide variety of industrial applications, such as water treatment systems, heating, ventilation and air conditioning systems, chemical and petrochemical industries, and others.

Electric actuators offer several advantages over conventional mechanical actuators, such as the ability to control valve opening with precision, enabling a more consistent and uniform flow of liquids and gases. In addition, they can be easily integrated into automation and control systems, allowing a more efficient and reliable operation of the system as a whole.

Avaliable controlers:

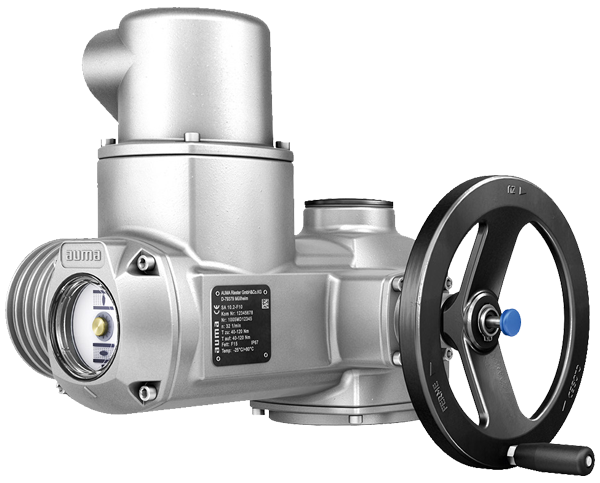

MULTI-TURN ELECTRIC ACTUATORS

SA and SAR type

Actuators of the SA type range for open-close duty and positioning duty are rated for class A and B or types of duty S2 – 15 min. A special version for longer running is available for the S2 – 30 min duty. The modulating actuators of the SAR range are rated for class C or types of duty S4 – 25 %. Special versions for S4 – 50 % and S5 – 25 % are also available. Actuators of type range SA/SAR can be combined with various controls from simple OPEN-CLOSE control to the micro-controlled version with logging of operating data or fieldbus interface.

DESIGN FEATURES SA:

- Torque range from 10 Nm to 32,000 Nm

- Output speeds from 4 to 180 rpm

- Limit and torque sensing

- Available with 3-ph AC, 1-ph AC and DC motors

- Handwheel for manual operation

DESIGN FEATURES SAR:

- Torque range from 15 Nm to 4,000 Nm

- Modulating torque range from 15 Nm to 1,600 Nm

- Max. number of starts 1,200 c/h

- Output speeds from 4 to 90 rpm

- Limit and torque sensing

- Available with 3-ph AC, 1-ph AC motors

- Handwheel for manual operation

AMBIENT CONDITIONS:

- High enclosure protection

- High quality corrosion protection

- Wide ambient temperature ranges

OPTIONS:

- Intermediate position switches

- Switches in tandem version

- Remote position transmitter

- Magnetic limit and torque Transmitter

- Mechanical position indicator

- Functional safety: Up to SIL 2 in selected configurations

INTERFACES:

- Electrical connection via AUMA plug/socket connector (optionally terminals)

- Cable entries in different versions

- Output drive types according to ISO and DIN Standards

MATCHING CONTROL PRODUCTS:

- AC Controls

- AM Controls

SA MULTI-TURN ELECTRIC ACTUATOR DATA SHEET (EN)

AC CONTROL DATA SHEET (EN)

AM CONTROL DATA SHEET (EN)

Avaliable controlers:

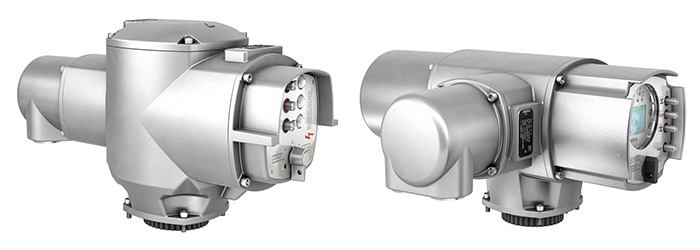

PART-TURN ELECTRIC ACTUATORS

SQ and SQR type

Actuators of the SQ type range for open-close duty and positioning duty are rated for class A and B or types of duty S2 – 15 min. The modulating actuators of the SQR range are rated for class C or types of duty S4 – 25 %. Actuators of type range SQ/SQR can be combined with various controls from simple OPEN-CLOSE control to the micro-controlled version with logging of operating data or fieldbus interface.

DESIGN FEATURES SQ:

- Torque range from 50 Nm to 2,400 Nm

- Swing angles from 75° to 105°

- Operating time ranges for 90° from 4 s to 100 s

- Limit and torque seating

- 3-ph AC and 1-ph AC motors

- Handwheel for manual operation

- Mechanical Position indicator

DESIGN FEATURES SQR:

- Torque range from 50 Nm to 2,400 Nm

- Modulating torque from 75 Nm to 1,200 Nm

- Max. number of starts 1,500 c/h

- Swing angles from 75° to 105°

- Operating time ranges for 90° from 8 s to 100 s

- Limit and torque seating

- 3-ph AC and 1-ph AC motors

- Handwheel for manual operation

AMBIENT CONDITIONS:

- High enclosure protection

- High quality corrosion protection

- Wide ambient temperature ranges

OPTIONS:

- Intermediate position switches

- Switches in tandem version

- Remote position transmitter

- Magnetic limit and torque Transmitter

- Functional safety: Up to SIL 2 in selected configurations

INTERFACES:

- Electrical connection via AUMA plug/socket connector (optionally terminals)

- Cable entries in different versions

- Output drive types according to ISO and DIN Standards

MATCHING CONTROL PRODUCTS:

- AC Controls

- AM Controls