DXC SERIES

DXO SERIES

JXC SERIES

FN SERIE

DX-JX SERIES SANITARY

Hygienic Series

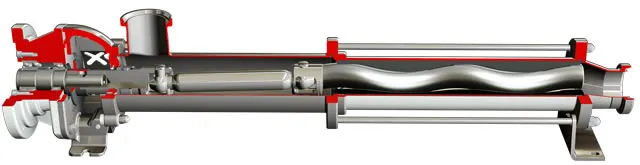

The DX hygienic pump series is state of the art for the food, pharmaceutical, chemical and cosmetic industries. The complete sanitary design, in compliance with standards EHEDG and 3A, ensures maximum sanitisation.

These pumps are top rated for ” Clean In Place” and ” Sterilising In Place”. The geometry of the pumps isdesigned specifically to allow drainage and avoid

dead zones. Each component is manufactured with the highest level of finish and utmost cleanliness. As well as the parts that come in contact with the product, the block and base plate (when requested) are made of stainless steel (standard in AISI 304).

The available fittings include DIN 11851, Clamp ISO 2852, Clamp ASME-3A, Clamp DIN 32676, RJT, SMS 1145 and lastly Garolla and Macon for the wine industry. The complete range ofpumps can be manufactured with block construction (DXO SERIES and DXC SERIES) or bearing housing with independent shaft (JXO SERIES and JXC SERIES).

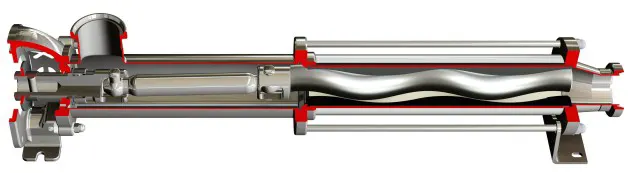

DX Series: the drive is coupled directly to the pump via a flange. This solution is extremely cheap and compact, considerably reducing installation costs and simplifying maintenance. The stress generated by the hydraulic part is supported by the drive itself. Each drive used is adequately selected based on their specific technical parameters and are subject to numerous duration tests with heavy loads.

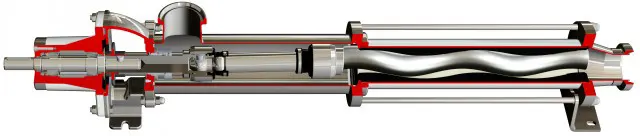

DXC Series: The DXC series is a hygienic pump with pin, standard to the DN series. This solution combines excellent sanitisation characteristics thanks to the design and casing completely free of dead zones and stagnation, together with the performance of the pin-type joint patented in the Diamond series. Lubrication of the pin is independent of the pumped product, therefore it is also suitable for abrasive fluids.

DXO Series: The DXO series is a hygienic pump with open joint. It is the solution with the best sanitisation characteristics thanks to the design of the casing and the rotating parts completely free of dead zones and stagnation. The pin-type joint has been suitably sized to guarantee long duration. Lubrication of the joint is guaranteed by the product thanks to its open design, therefore it is suitable for non-abrasive fluids. Performance improves considerably when pumping lubricant products.

JX Series: the drive is connected to the shaft inlet via a flexible coupling. This configuration is the best solution in terms of performance and durability All the stress generated by the pump is absorbed by the bearings in the housing. These bearings have very high resistance against loads. They are assembled with extreme precision on the highest quality manufactured parts. It is the best solution when you want to guarantee duration and reliability, yet with greater installation space requirements. The bearing unit designed by us is modular and can be adapted to a DX Series pump with lantern. It is state of the art for this type of installation.