TSURUMI SUBMERSIBLE MIXERS

Submersible mixers are the most practical and efficient solution for mixing, agitating, homogenizing and equalizing wastewater at treatment facilities. They are used in aerobic as well as anaerobic and anoxic stages of wastewater treatment processes to prevent sedimentation and maintain constant concentration levels in the tanks. Propellers for mixers are sized, shaped and driven at speeds designed to match the site requirements.

FEATURES

- MOTOR:Premium IE3 class cold-running motor for high efficiency and minimal energy use. Insulation class H (180°C).

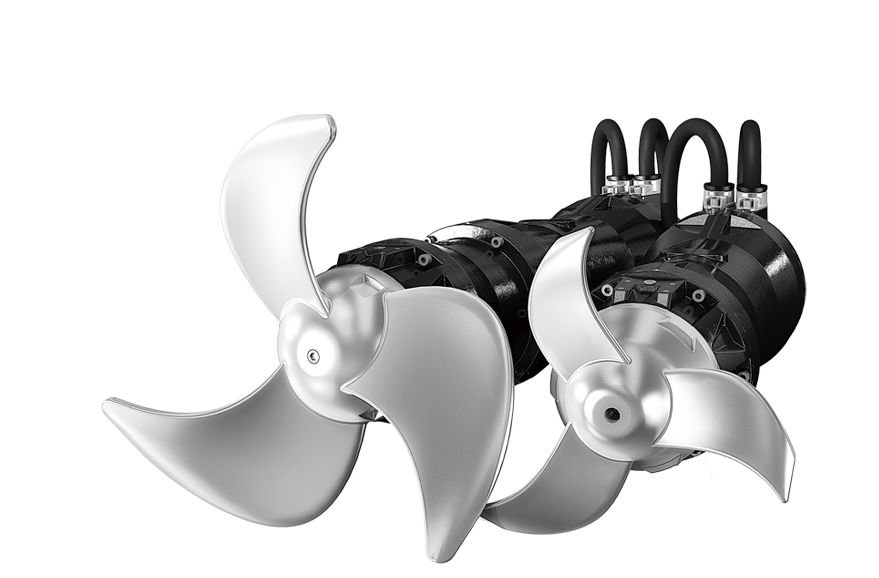

- PROPELLER: Cast AISI 316 stainless steel propeller, designed with specially shaped blades to ensure high hydraulic efficiency and prevent fouling with filaments and solids. Extra thick for ruggedness and reliability even in heavy-duty conditions.

- MECHANICAL SEALS: Two silicon carbide (SiC) mechanical seals in large, inspectable oil chamber. MMR 650-series equipped with 3 mechanical seals. (2 in the oil chamber and 1 in the gearbox)

- MONITORING: Water sensor detecting seepage into the mechanical seal oil chamber. The temperature sensor prevents possible damage due to overheating of the motor. Bearing temperature sensors are available on request. (other monitoring options are available for the MMR 650-series on request)

- CABLE GLAND: Innovative cable gland system with cable holder. The universal thread ring-nut can be removed to fix a rigid or flexible duct to the cable gland to protect the cable from physical and mechanical stresses.

- BEARINGS: Ball bearings with lifetime lubrication designed to guarantee 100,000 working hours. Temperature sensor on request.

- INSTALLATION: Wide range of rugged stainless steel accessories for optimal installation in relation to the system layout and when replacing existing devices.

- REDUCTION GEARBOX [MMR 650-series]: Rugged planetary reduction gearbox which provides high reduction ratios and torque transfer and withstands heavy radial loads, with compact size and light weight.