MILTON ROY MIXING

HR MIX MIXERS

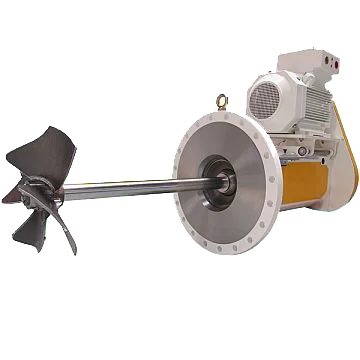

HR1A Series

Standardized high-speed agitators.

Applications: Homogenization, dissolving, reagent preparation,

neutralization.

- Marine propeller for low pumping flows (Ø 100 to 200 mm).

- Speeds: 1000 RPM and 1500 RPM.

- Power: From 0.25 to 1.5 kW.

- Tank volume: From 40 L to 3 m³.

- Temperature: Ambient.

- Pressure: Atmospheric.

HR1A MIXER DATA SHEET (EN)

HR2A/B Series

Standardized low-speed agitators.

Applications: Homogenization, dissolving, reagent preparation, neutralization.

- Axial 4×45º blade turbine (Ø 350 to 800 mm).

- Speeds: From 75 to 100 RPM.

- Power:From 0.37 to 3 kW.

- Tank volume: From 200 L to 10 m³.

- Temperature: Ambient.

- Pressure: Atmospheric.

HR2A/B MIXER DATA SHEET (EN)

HR5A/B Series

Standardized low-speed agitators.

Applications: Flocculation

- Two-bladed impeller (Ø 300 to 4000 mm).

- Speeds: from 7 to 96 RPM.

- Power:From 0.37 to 3 kW.

- Tank volume: From 100 L to 750m3.

- Temperature: Ambient.

- Pressure: Atmospheric

HR5A/B MIXER DATA SHEET(EN)

HR6A/B Series

Standardized agitators with reducer.

Water treatment applications: Homogenization, preparation of additives and polymers, suspension, fast mixing. Application in other industries: dissolving, heat transfer, storage, suspension.

- Thin profile 3 blades propellers with high efficiency and high flow (Ø 200 to 2000 mm).

- Speeds: from 52 to 295 RPM.

- Power:From 0.37 to 11 kW.

- Tank volume: From 200 L to 200m3.

- Temperature: Ambient.

- Pressure: Atmospheric

HR6A/B MIXER DATA SHEET (EN)

SPECIAL MIXERS

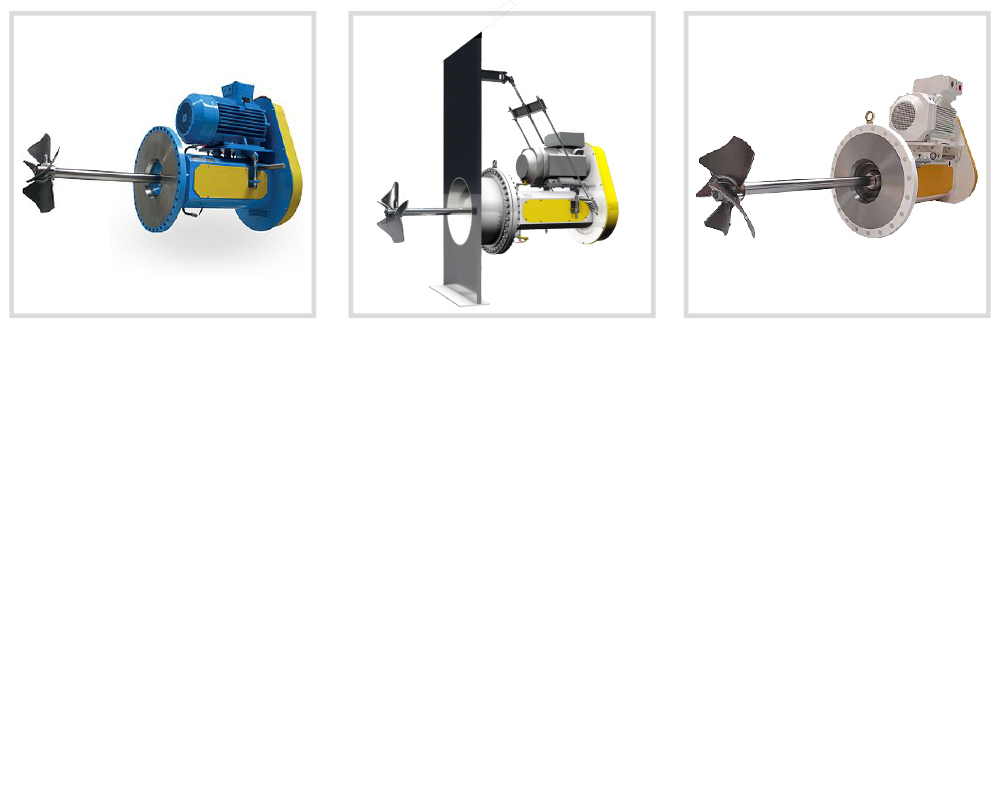

REALIABLE TANK MIXERS SIDE – Entry Series

Compact. Powerful. Consistent Results

Mixing technology for all your crude oil & derivatives storage tanks Typically, large storage tanks require the constant mixing of contents, but roof-mounted agitators cannot support the heavy load. In response, Milton Roy Mixing has developed a specific range of side-entry mixers for large-volume storage tanks.

Our side-entry mixer is mounted quickly and easily to the tank flange and delivers the most effective blending results in an extremely efficient unit. Our innovative small diameter SABRE® impeller allows for reduced energy consumption and easy installation.

In addition, we can ensure proper agitation using numerical simulation of fluid flows (CFD). This helps to forecast and predict the storage tanks mixing with no dead zone, and lower energy consumption compared to conventional solutions. We can also provide an adjustable agitator to increase the scope enclosure.