STEAM TRAPS

KLINGER’s Steam Traps are the best cost-benefit in condensate drainage.

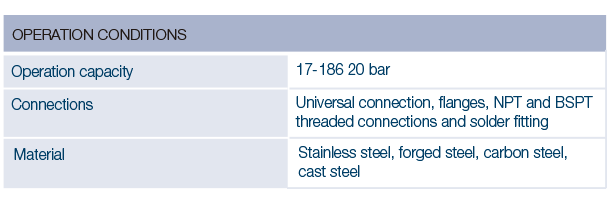

THERMODYNAMIC STEAM TRAP

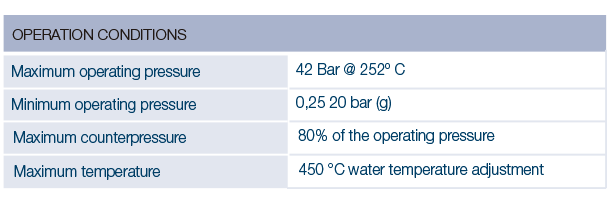

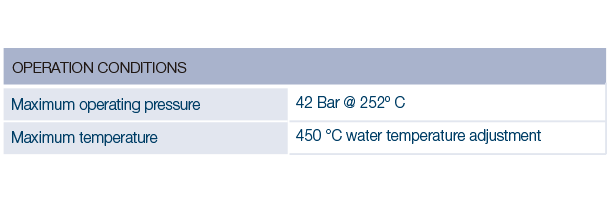

Thermodynamic Traps are low-cost options for draining condensate in steam distribution lines up to 42 bar pressure. Designed with three outlet holes, offers stable operation disk, it offers a stable disc operation, which is linked to the seat hardening, assuring a longer life to the steam trap.

MATERIALS:

- Cover: stainless steel AISI 420;

- Body: stainless steel AISI 420 with hardened seat;

- Disc: stainless steel AISI 420.

CONNECTIONS:

DN ½’’, ¾’’, and 1 ’’ red NPT and BSPT, BW and SW welding or union with flanges adapted ANSI class B16,5 150#, 300# or 600#.

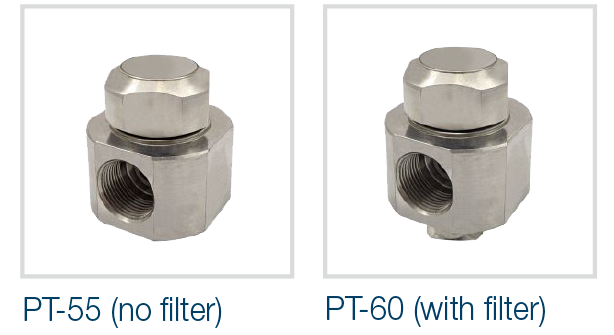

UNIVERSAL CONNECTOR THERMODYNAMIC TRAPS

Designed with an universal connector attached, the UPT allows the steam trap removal without the need of interference in the pipeline. Two screws secure the steam trap to the connector block, which , which remains installed in the pipeline without the need for flanges or connections. To remove the steam trap, the respective pipe section must be blocked and depressurized..

Ideal for condensate drainage in saturated steam distribution lines up to 42 bar pressure.

Available in versions with filter – UPT 60, and also without filter – UPT 55.

MATERIALS:

- Cover: stainless steel AISI 420;

- Body: stainless steel AISI 420 with hardened seat;

- Disc: stainless steel AISI 420;

- Filter: Stainless steel AISI 314.

CONNECTIONS:

- Steam Trap: universal type;

- Connector block: DN ½” e ¾”, NPT and BSPT thread connections.

THERMOSTATIC STEAM TRAP

Simple and robust, , the thermostatic steam trap is an excellent solution for trapping condensate in small equipment up to 42 bar pressure. The thermostatic drive takes place through a bimetallic device that guarantees efficiency and durability.

MATERIALS:

- Cover: stainless steel AISI 420;

- Body: stainless steel AISI 420 with hardened seat;

- Bi metallic element: GB14.

CONNECTIONS:

DN ½’’, ¾’’, and 1 ’’ red NPT or BSPT.

BALL FLOAT STEAMTRAP

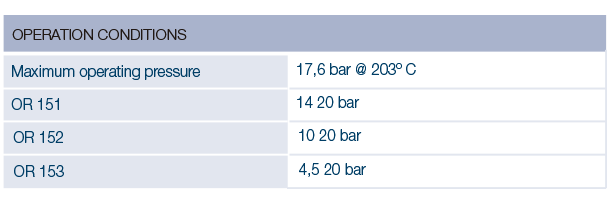

The ball float steam trap line is a cost effective option for condensate drainage in heating equipment for low pressure steam such as heat exchangers, streamers, liners, etc. It allows easy and low cost maintenance and has the bi-metallic thermostatic air eliminator as standard, which assures efficiency and durability.

MATERIALS:

- Body and Cover DN ½ ‘’ and ¾ ‘’: Cast iron ASTM A 126 – B;

- Body and Tampa DN 1 ‘’, 1.½” and 2”: Cast iron GGG-40;

- Float: AISI 304;

- Plug: AISI 440 C;

- Thermostatic Element: GB14.

CONNECTIONS:

- NPT Thread, BSPT DN ½’’, ¾’’, and 1’’.

- ANSI B16.5 Class Flange 150# DN 1‘’, 1.½” and 2”.

- Flange ANSI B16.5 Class 125# and 250# DN 1‘’, 1.½” and 2”.

INVERTED BUCKET STEAM TRAP

KLINGER creates specifications, specifies, also trades and provides technical assistance for inverted bucket steam traps line. These steam trap models enable efficient condensate drainage for application in all steam equipment types. As the steam traps operate efficiently for long periods, steam traps provide significant energy savings, in addition to reducing labor and replacement costs.

Inverted bucket steam traps continuously drain and, although there is intermittent discharge, there is no condensate return or accumulation. These steam traps are also resistant to water hammering.

All these steam traps are repairable, allowing even greater savings with maintenance services.

A leverage system multiplies the force exerted by the bucket to open the valve against system pressure. The mechanism is floating and has no fixed gaskets that can cause wear or friction.