KHD SEGMENTED BALL VALVES

KHD Segmented Ball Valves are also known as V-port ball valves. The ball valve core is designed with a special V shape notch. This contributes to strong shear force and precise flow control.

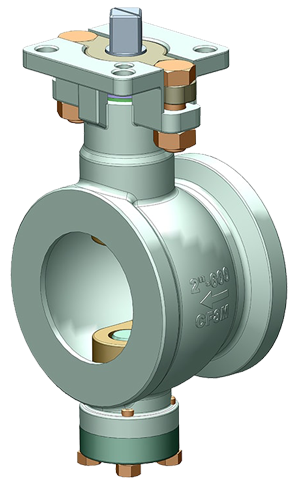

Common are wafer type segmented ball valves and flanged type segmented ball valves.

Flanged ball valves provide effective control of oil and gas operations.

Their characteristic feature is the flanged ends that are bolted to the oil and gas piping.

A wafer-type ball valve is defined as a flangeless design. Wafer-type ball valves feature a hinged, flap-like disk (the wafer) that is used to allow and restrict liquid flow.

Soft seats: are made of thermoplastic materials such as PTFE. They are ideal for applications where chemical compatibility is important and where the tightest possible seal is essential. However, soft seats are not recommended for dirty or abrasive process fluids. Soft seats can break under these conditions, causing leaks in the valve.

Metal seats: incorporate a metal-to-metal seal between the seats and ball of the valve assembly. In general practice, metal seats can stand up to extreme flashing, hydraulic shock, abrasive process fluid, and high temperatures. They are also ideal for high erosion or corrosion applications