ENGINEERING

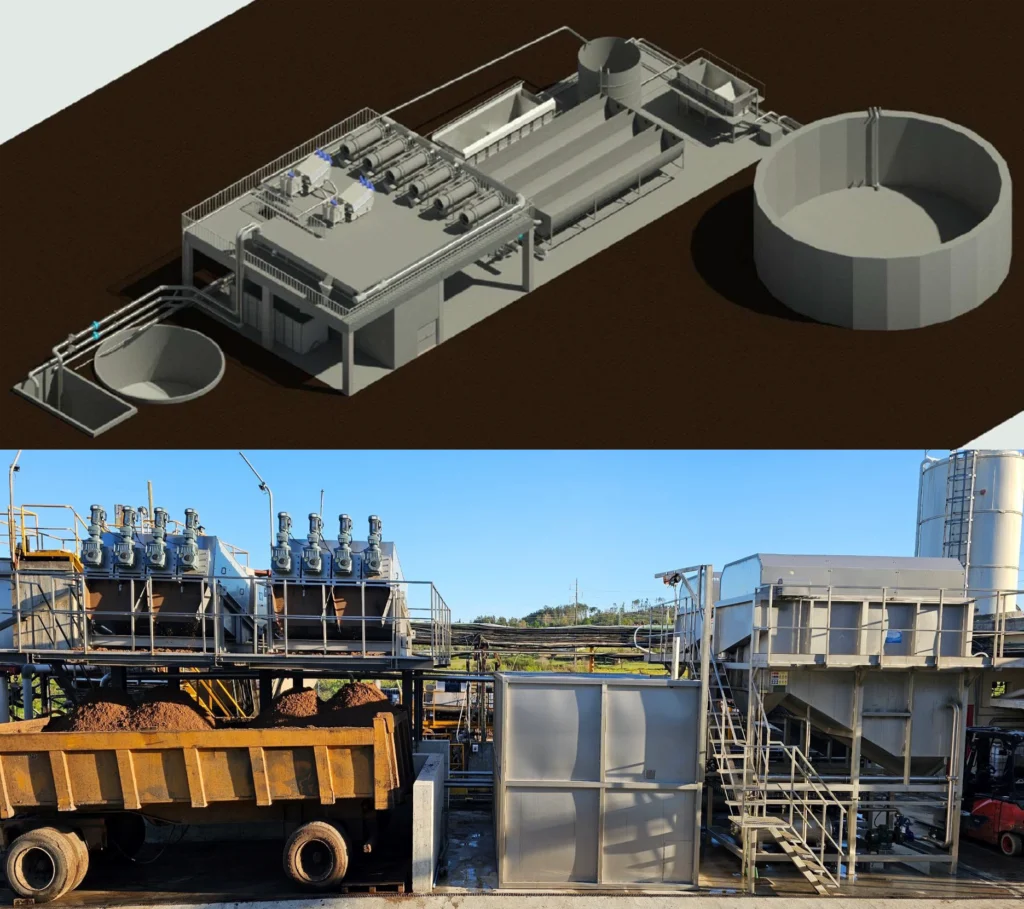

KLINGER Portugal Water Treatment

We seek to understand the needs of our customers within the wastewater market to present the best solutions.

Global supply of WWTP, design and construction

At KLINGER Portugal we believe that industrial wastewater treatment is built on the ideal synergy between efficiency, innovation and environmental responsibility.

We aspire to be an industry leader, dedicated to providing customized and innovative solutions to meet the unique needs of our customers.

Areas of activity:

- Dairy Industry

- Slaughterhouses

- Recycling industry

- Textile Industry

- Etc.

Including chemicals applications, maintenance, energy management, slurry management, analyses management, engineering consulting.

Thermal hydrolysis technology

KLINGER Portugal, collaborates in Portugal with CAMBI Group AS, a world leader in the supply of thermal hydrolysis technology for waste sludge treatment and advanced anaerobic digestion.

Thermal hydrolysis technology is a process applied in wastewater treatment plants, with anaerobic digestion. Thermal hydrolysis exposes waste sludge or other types of thickened organic waste to high temperature and pressure. It is a similar process to the use of steam for meal preparation in our homes.

Thermal hydrolysis advantages

- Increased biogas production

- Improved biosolids dewatering

- Increased digester throughput

- Lower carbon footprint

- Low maintenance, easy to operate

- High-quality biosolids

Where does thermal hydrolysis fit?

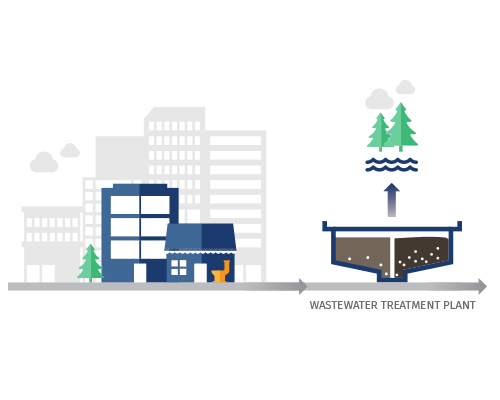

The thermal hydrolysis process is best suited for large volumes of homogeneous organic waste. The most common feedstock is sewage sludge, collected from an urban area to a wastewater treatment plant, through a municipal sewage network.

Before returning to nature, the wastewater undergoes a multi-step treatment process to remove organic matter, nutrients and pollutants, in line with local regulations. The first step removes mostly inorganic material, producing primary sludge. Secondary sludge with high organic content is separated in the next step.

In some cases, food waste or dewatered sludge may be brought from other locations and mixed with the sludge produced on-site.

A sludge line comprises all sludge processing steps at a wastewater treatment plant. Water utilities invest in many different sludge treatment technologies, to recover energy or nutrients from the sludge, reduce odours, eliminate pathogens or meet other regulatory requirements.

Most medium- and large-size wastewater treatment plants recover energy from the sludge via anaerobic digestion. The resulting biogas covers local energy needs or is sold as electricity or natural gas. Thermal hydrolysis is a sludge treatment technology used in conjunction with and improving anaerobic digestion.

The sludge line design and sludge management practices often have considerable impact on water utility balance sheets. Cambi makes a difference by optimal integration of our proven thermal hydrolysis process into any sludge line.

After anaerobic digestion, the sludge is dewatered before final disposal or utilisation. Thermal hydrolysis simplifies sludge management and disposal in several ways:

- as biogas production increases, less digestate is left;

- final dewatering is less energy-intensive;

- the volume of dewatered biosolids is much lower, hence cheaper to handle;

- the dewatered biosolids are pathogen-free, low-odour, easy to store and transport.

By investing in thermal hydrolysis, water utilities often gain new options for sludge biosolids disposal, such as delivering it to farmers for agriculture.

In areas where incineration is required, the resulting biosolids product has higher calorific value, which may translate into lower gate fees.

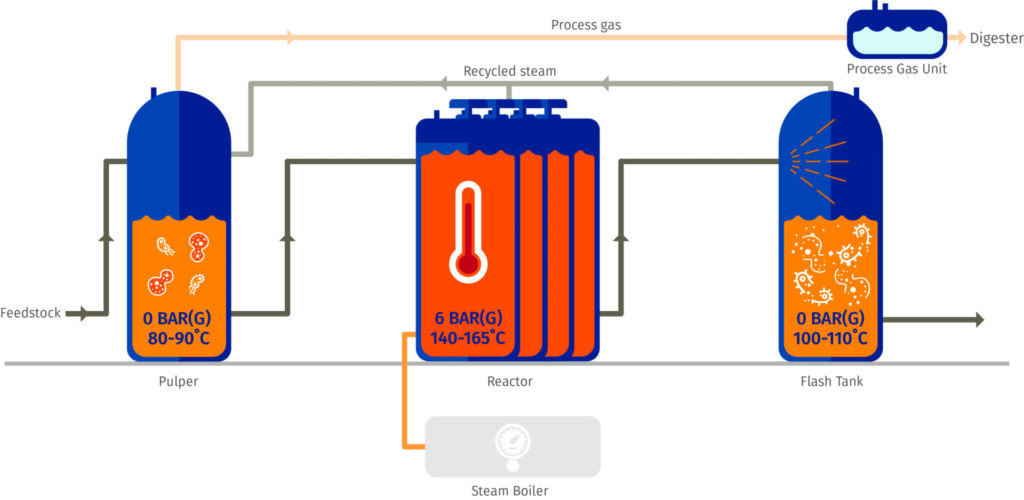

How does thermal hydrolysis work?

Thermal hydrolysis is a process technology applied in wastewater treatment plants with anaerobic digestion. Thermal hydrolysis exposes sewage sludge or other types of wet organic waste to high temperature and pressure. The process is similar to preparing meals using steam.

- From the wastewater treatment plant’s primary and secondary treatment units, raw sewage sludge is collected and dewatered to 16-18% dry solids. This thickened sludge is continuously fed into the pulper. The pulper has the role to homogenise and pre-heat the sludge to a temperature close to 100°C, using steam recovered from the flash tank.

- From the pulper, the warm sludge is fed continuously to the reactors, in a sequential process that ensures sealed batches of sludge in each reactor. Once a reactor fills up, sludge flows to the next available one. There are typically between 2 and 5 reactors in a Cambi thermal hydrolysis train, depending on sludge volume, reactor size and hydraulic retention time. When the reactor is full and sealed, steam is pumped to raise the temperature to 160 to 180°C at a pressure of about 6 bars. The thermal hydrolysis process is typically set at 20 to 30 minutes for each batch, to ensure pathogen kill.

- From the reactor, the now sterilised and hydrolysed sludge is passed to the flash tank, which operates at atmospheric pressure. The sudden pressure drop leads to substantial cell destruction for the organic matter in the sewage sludge. The steam generated by the pressure release is returned to the pulper to preheat the incoming sludge. Leaving the flash tank, the sludge is cooled to the typical temperature for anaerobic digestion, in heat exchangers. Then it is fed to the anaerobic digesters.

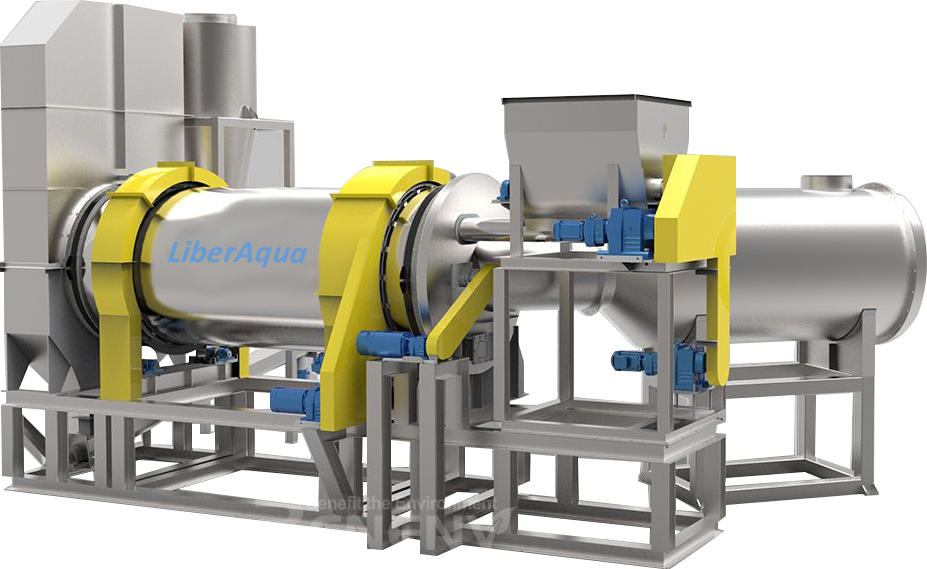

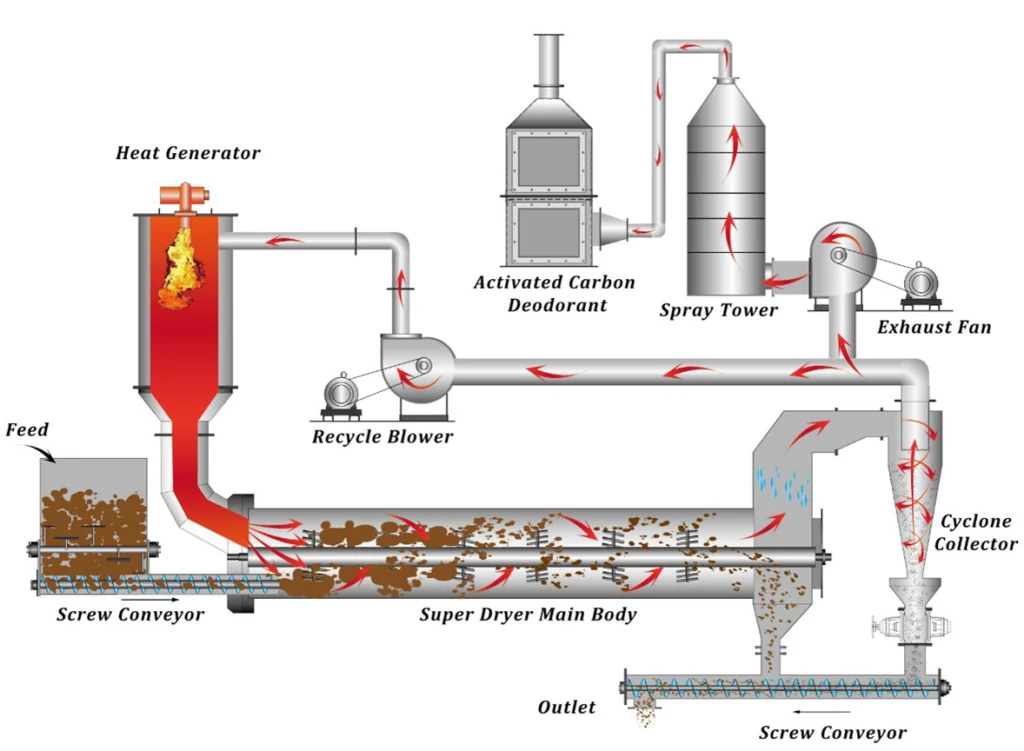

Super Rotary Sludge Dryer

Main advantages:

- Robust and reliable technology, used for over 40 years. Hundreds of installations in operation.

- Direct heating method by hot air, without the formation of dioxins or hazardous substances.

- Allows the use of different types of fuels.

- The patented design of the disintegrator allows continuous drying of solids, preventing clogging and clogging.

- It includes an integrated system for the treatment of gaseous emissions using active carbon.

Compact sludge composting systems

Main advantages:

- Very small footprint

- High temperature aerobic composting: faster / less odour formation. Odour treatment

- Significant waste reduction (< ecological footprint)

- Very automated solution

- Product can be used as organic fertiliser (subject to authorisation by competent body)

Other engineering system

KLINGER Portugal offers:

- Industrial sludge composting systems

- Installation of diffuser nets

- Removable stainless steel aeration nets and stainless steel structures