HYBRID PACKINGS

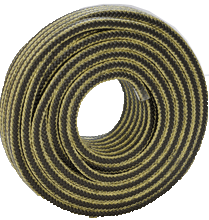

For those applications where an unusual combination of service demands are faced so a specially constructed hybrid packings may be required and hybrid packings are suitable for it.

This is achieved by combining two or more yarns by special braiding methods, and adding selected lubricants. These Hybrid packings are primarily designed for use in specialized duties, but can be equally effective in many more standard applications.

KLINGER recommends HYBRID packings in difficult applications where high stresses are involved and the packing is required to offer a tight seal under high pressure, eg reciprocating pumps.

KLINGER TOPLINE K4311

A hybrid packing that combines the properties of Aramid-fibre and PTFE-yarns around a silicone rubber core with PTFE and silicone lubricant. A strong packing suitable for use where shaft wear is a consideration.

» An excellent dynamic packing for rotary and reciprocating duties

» Suitable for abrasive and viscous media

KLINGER TOPLINE K4313

TopLine hybrid packing that combines the properties of Aramid-fibre and PTFE-yarn around a silicone core to produce a high-strength packing suitable for use with abrasive and viscous media, PTFE yarn ensures shaft wear is kept to a minimum.

» An excellent dynamic packing for rotary and reciprocating duties

» Suitable for abrasive and viscous media