PROGRESSIVE CAVITY PUMPS

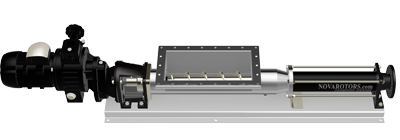

FLANGED INDUSTRIAL SERIES

The Flanged Industrial Series is the basis of the Diamond series.

The robust cast casings, also in the stainless steel model, with large inspection ports included, make this an ideal product for the toughest applications. The Diamond DN and JN series are the best solution for a wide range of fluid pumping industries. They are synonymous with sturdiness, reliability, performance and application flexibility. Available with UNI, DIN and ANSI flanged and GAS BSP threaded connections.

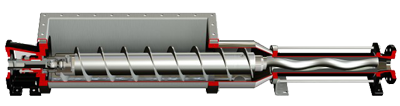

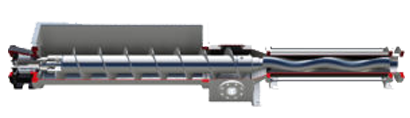

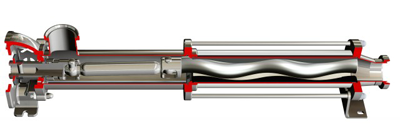

DN SERIES

The drive system is coupled directly to the pump by means of a flange. This solution is extremely economical and compact, considerably reduces installation costs and simplifies maintenance. The forces generated by the hydraulic part are

supported by the drive system itself.

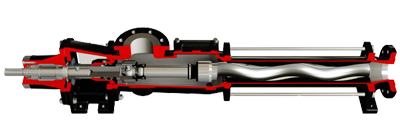

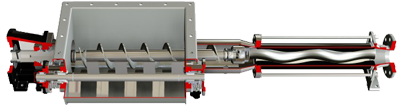

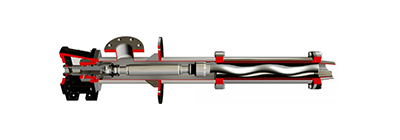

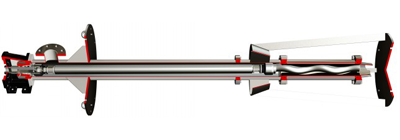

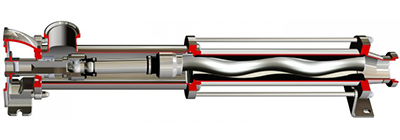

JN SERIES

The drive is connected to the free bare shaft via a flexible coupling. This solution is the best solution in terms of performance and durability. All the forces generated by the pump are absorbed by the bearings. The bearing unit of our design is modular and can be installed at a later date in a closecoupled pump of the DN series.

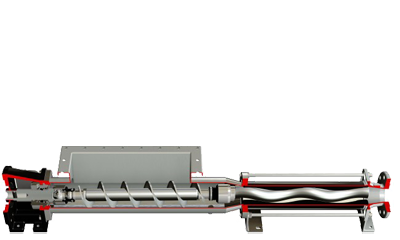

HOPPER PUMPS

The open hopper pumps with hydraulic auger feed screw are ideal for handling high-consistency materials with a low degree of flowability and high solid content.

They are available in 7 different construction types, each with different screws and hoppers based on the type of product to be pumped.

All pumps can be made with a close coupled arrangement or a bearing unit arrangement and free bare shaft (JH SERIES, JHS SERIES, JHP SERIES, JHB SERIES and JHSB SERIES) excepting the DHE SERIES which has a built-in gear motor.

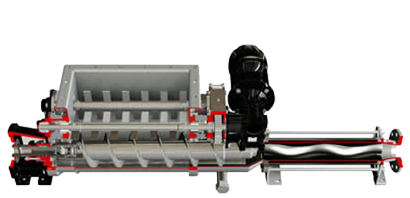

DH SERIES

Standard model equipped with rectangular hopper and an auger feed screw that moves the product to the hydraulic part. The length can be adapted to suit the application. Suitable for pumping materials with low flow-ability and up to 18% solids content which do not create or have a tendency to bridge.

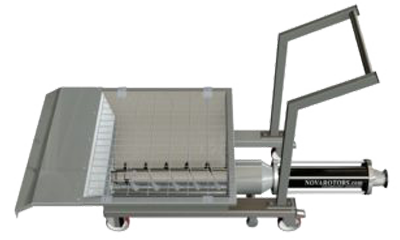

DHE SERIES

This model has a large eccentric hopper, with integrated trolley, ideal for the wine industry in conjunction with destemmers-crusher. For pumping crushed grapes with or without stems. Extremely compact standard construction with all parts made from AISI 304 stainless steel.

The worm gear motor significantly reduces the pump’s footprint. The pump is supplied with a safety mesh on the hopper, protection guard for the drive system and a large handle that can accommodate electric panels and inverters. It can be supplied with a level probe on the hopper for automatic shutdown of the pump.

DHS SERIES

This model features a rectangular hopper and enlarged auger feed screw that moves the product to the hydraulic part. The length can be adapted to suit the application. Suitable for pumping high viscosity materials with low flow-ability and up to 28% solids content which do not tend to bridge. The screw drive shaft features a special integrated joint protection.

DHP SERIES

Model fitted with wide hopper, single bridge breaker shaft and auger feed screw that moves the product to the hydraulic part. Easy handling of materials with a low degree of flow ability and prone to bridging. Particularly suitable for easily compressible, large mixtures or solid materials such as whole fruits and vegetables. Ideal for food applications such as grapes, whole fresh grapes, chopped tomatoes or doughs for the confectionery industry. Standard AISI 304 or AISI 316 stainless steel construction. No dead zones and easy to clean design.

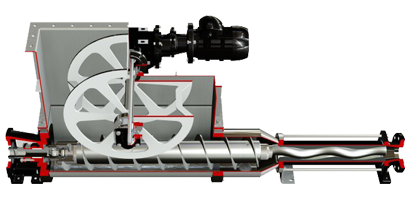

DHB SERIES

This model features a hopper with double bridge breaker shaft and an enlarged auger feed screw that moves the product to the hydraulic part. The length can be adapted to suit the application.

Suitable for pumping highly viscous, non-flowing materials with up to 35% solids content with blocks that tend to bridging.

The screw drive shaft features a special integrated joint protection.

DHSB SERIES (DHS WITH “B” MODULE)

This model features a rectangular hopper and an enlarged auger feed screw that moves the product to the hydraulic part. The hopper is fitted with a “B” Module which features a special wheel device that feeds the screw to prevent bridging and increase flow ability of the plastic or pseudo plastic materials. Suitable for pumping non-flowing materials with up to 40% solids content with blocks that tend to bridging. It is particularly effective in pumping products that tend to plasticize. The screw drive shaft

features a special integrated joint protection.

DHS-T SERIES

This model features a rectangular hopper and an enlarged auger feed screw that moves the product to the hydraulic part. It is designed for the Biogas sector for pumping silage with the

injection of phase liquid at the inlet to increase pump-ability of the solids. The separate inlet provides the connections for the injection of liquids and has a rectangular bottom for collecting any stones that might enter the hopper and be conveyed away by the screw. This avoids damage to the hydraulic section. Moreover, a large additional inspection port is provided with quick couplings for easy removal of solid deposits from the inlet.

VERTICAL SERIES

The Vertical series is the ideal solution for pumping viscous or non-viscous, abrasive and aggressive materials from tanks and wells. These pumps are available with UNI, DIN and ANSI and GAS BSP discharge flanged connections; whereas the liquid suction port is designed specifically for priming the product in which it is immersed.

The length can be adapted to suit the installation requirements. The stainless steel version (AISI 304 or

AISI 316) is supplied with a stator jacket as standard to prevent corrosion of the stator.

There are two standard configurations: the short version and the long version. The difference is in the installation length with which they are constructed. They are always constructed in the close-coupled version.

DV SERIES – SHORT VERSION

The short version is compact robust and very easy to install.

DV SERIES – LONG VERSION

The long version is ideal for installation in deep wells or tanks

and feature a number of dedicated optimizations such as the removable inlet for easy maintenance of the rotor, stator and coupling. A fundamental feature is the downhole plate with clamping cone to make the pump extremely stable and vibration-free even in extreme conditions of use.

HYGIENIC SERIES

The sanitary pump series is state of the art and perfect for food, pharmaceutical, chemical and cosmetic industries. The complete sanitary design, in compliance with EHEDG and 3A standards, ensure maximum sanitization. These pumps are top rated for “Clean in Place” and “Sterilisation in Place” procedures. The geometry of the pumps is designed specifically to allow complete draining and avoid dead zones. Each single component is manufactured with the utmost attention to finishing details and is thoroughly cleaned.

As well as the parts that come into contact with the product, the block construction and base (when requested) are also made of stainless steel (standard in AISI 304).

The available fittings include DIN 11851, DIN 11864, Clamp ISO 2852, Clamp ASME-3A, Clamp DIN 32676, RJT, SMS 1145 and lastly Garolla and Macon fittings for the wine industry.

The complete range of pumps can be manufactured with block construction (DXO SERIES and DXC SERIES) or bearing unit and free bare shaft (JXO SERIES, JXC SERIES).

DXO SERIES

The DXO series is a hygienic pump with open joint. The design of its casing and rotating parts ensures that they completely free of stagnation points and dead zones, making it the absolute best for sanitary applications. The pin-type joint has been suitably sized to ensure a long life. Lubrication of the joint is guaranteed by the actual product thanks to its open design, consequently it is suitable for non-abrasive fluids. Performance improves considerably when pumping lubricants

DXC SERIES

The DXC series is a hygienic pump with closed pin joint (standard to the DN series) and ideal for abrasive sanitary applications. In all other respects it maintains all the sanitary features of the DXO series. Lubrication of the pin is independent of the pumped product, consequently it is also suitable for abrasive fluids.

GRINDERS – TG SERIES

SÉRIE DXO

Welcome in the “New Era” of grinders! An uniform and correct treatment of solids is necessary in wastewater application and sludge handling system. However, it is often difficult to choose the right solution at the right cost. Our TG series for solids size reduction it is one of the most innovative solutions that you can found in the market. We are proud for the extremely tough design combined with a flexible internal component configuration. This is the best approach to achieve benefits while preserving savings. Furthermore, the accessories and options that we designed allow us to create YOUR shredder.