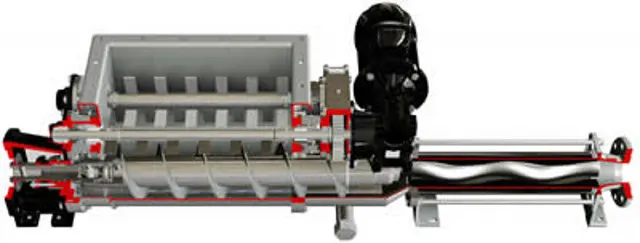

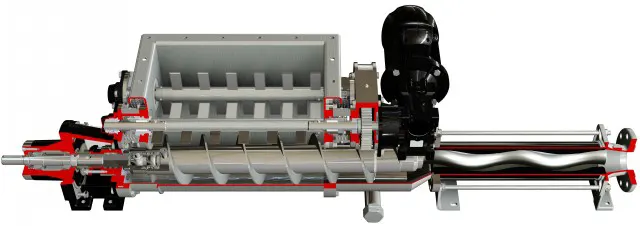

DHB SERIES

JHB SERIES

DHB-JHB DIAMOND SERIES

Hopper Industrial Series

Series with hopper an auger feed screw to convey directly the product to hydraulic part, are the ideal machines

for pumping viscous and non-flowing, with a very high solids content.

The DHS e JHS series are the hopper rectangular version with increased auger feed screw to the hydraulics. The length is customizable depending on application. Suitable for pumping substances poorly flowing up to 35% of dry substance with high viscosity which don’t tend to form a bridge or blocks. The auger feed screw integrates a special device for joint protection.

DHB series: the drive is coupled directly to the pump via a flange. This solution is extremely cheap and compact, considerably reducing installation costs and simplifying maintenance. The stress generated by the hydraulic part is supported by the drive itself. Each drive used is adequately selected based on their specific technical parameters and are subject to numerous duration tests with heavy loads.

JHB Series: the drive is connected to the shaft inlet via a coupling joint. This configuration is the best solution in terms of performance and durability. All the stress generated by the pump is absorbed by the bearings in the housing. These bearings have very high resistance against loads. They are assembled with extreme precision on the highest quality manufactured parts. It is the best solution when you want to guarantee duration and reliability, yet with greater installation space requirements. The bearing housing designed by us is modular and can be installed after a pump with the DHS series block housing. It is state of the art for this type of installation.

The DHS e JHS series are the hopper rectangular version with increased auger feed screw to the hydraulics. The length is customizable depending on application. Suitable for pumping substances poorly flowing up to 35% of dry substance with high viscosity which don’t tend to form a bridge or blocks. The auger feed screw integrates a special device for joint protection.

DHB series: the drive is coupled directly to the pump via a flange. This solution is extremely cheap and compact, considerably reducing installation costs and simplifying maintenance. The stress generated by the hydraulic part is supported by the drive itself. Each drive used is adequately selected based on their specific technical parameters and are subject to numerous duration tests with heavy loads.

JHB Series: the drive is connected to the shaft inlet via a coupling joint. This configuration is the best solution in terms of performance and durability. All the stress generated by the pump is absorbed by the bearings in the housing. These bearings have very high resistance against loads. They are assembled with extreme precision on the highest quality manufactured parts. It is the best solution when you want to guarantee duration and reliability, yet with greater installation space requirements. The bearing housing designed by us is modular and can be installed after a pump with the DHS series block housing. It is state of the art for this type of installation.